Distributors & Manufacturers

From standardizing quoting and order intake to automating tasks like margin monitoring and customer shipment notifications, The Lab knows exactly where to find your most valuable standardization, automation, analytics, and AI improvements.

Distributor & Manufacturers: The Lab's Knowledge Base

The Lab's Knows Your Organization—And the Most Valuable Improvements

Findings from 30+ years of The Lab’s work with manufacturers and distributors—including process improvements, best practices, KPI definitions, benchmarks, and automation use cases—are organized into a standard organizational taxonomy and stored in our knowledge base. We use these assets and make them available to our clients during engagements to rapidly accelerate transformation benefits.

Improvements and Benefits Are Highly Predictable—and Guaranteed

Typical Benefits for Distributors & Manufacturers—The Lab's "Big Rocks"™

Hit More/Miss Less

Grow Sales

• Retain existing customers

• Cross-sell existing customers

• Expand to new markets

New Sales Opps: 10% to 15%

Waste Less

Improve Productivity

• Decrease errors and related rework

• Automate value-added activities

• Reduce individual performance variance

Cost Savings: 20% to 35%

Keep More

Preserve Margin

• Reduce price variance for same SKUs

• Decrease unprofitable products, accounts

• Lose fewer overlooked, expired rebates

Margin Savings: 5% to 15%

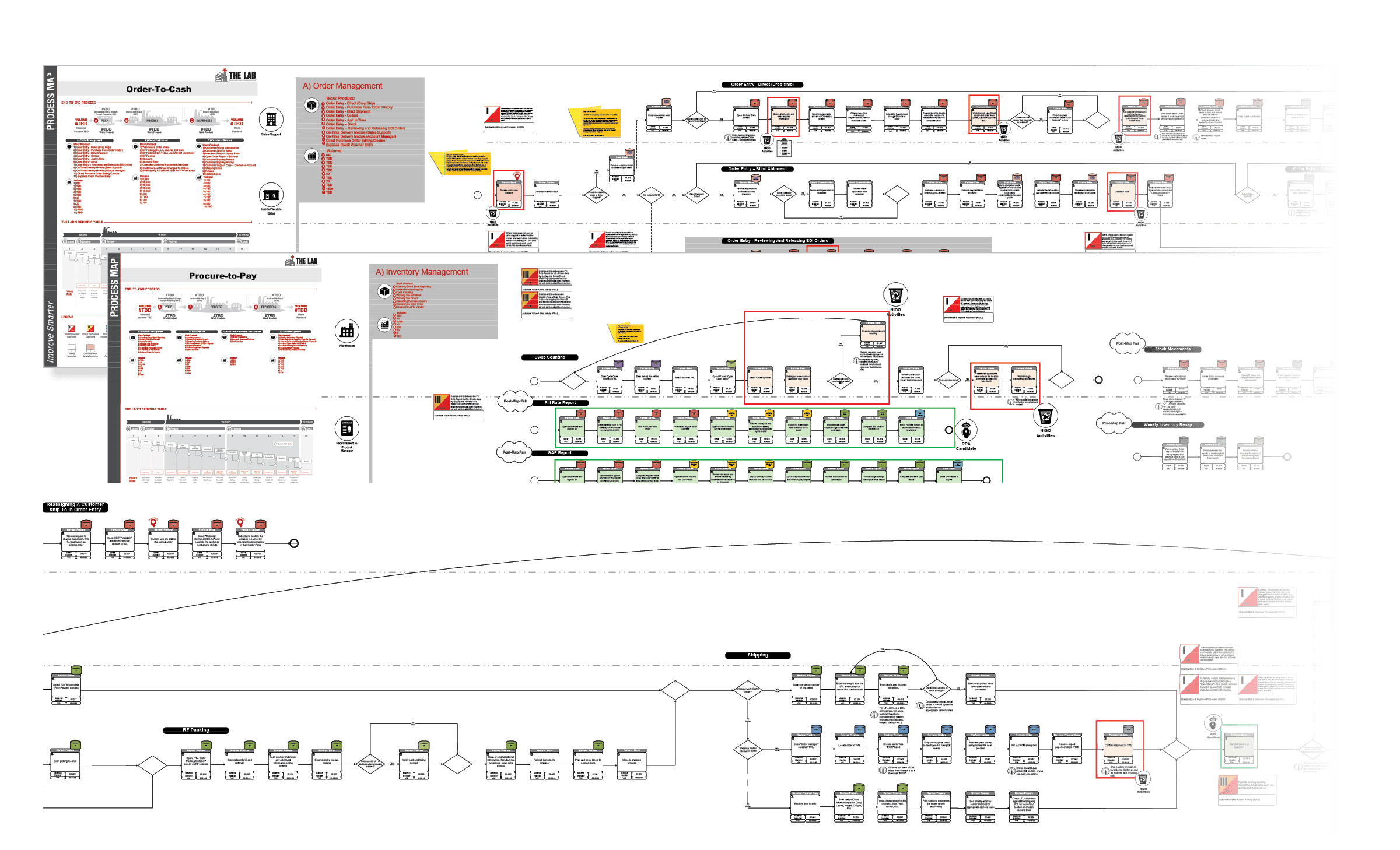

Process Mapping Services for Distributors & Manufacturers

Understand Your Major Business Processes and How to Improve Them

Rely on The Lab’s standardized process mapping experience and industry-leading process improvement team to rapidly document your current-state business processes—end to end. From order-to-cash and procure-to-pay to sales prospecting, we’ve mapped it all. We can do the same for your organization in less than 8 weeks.

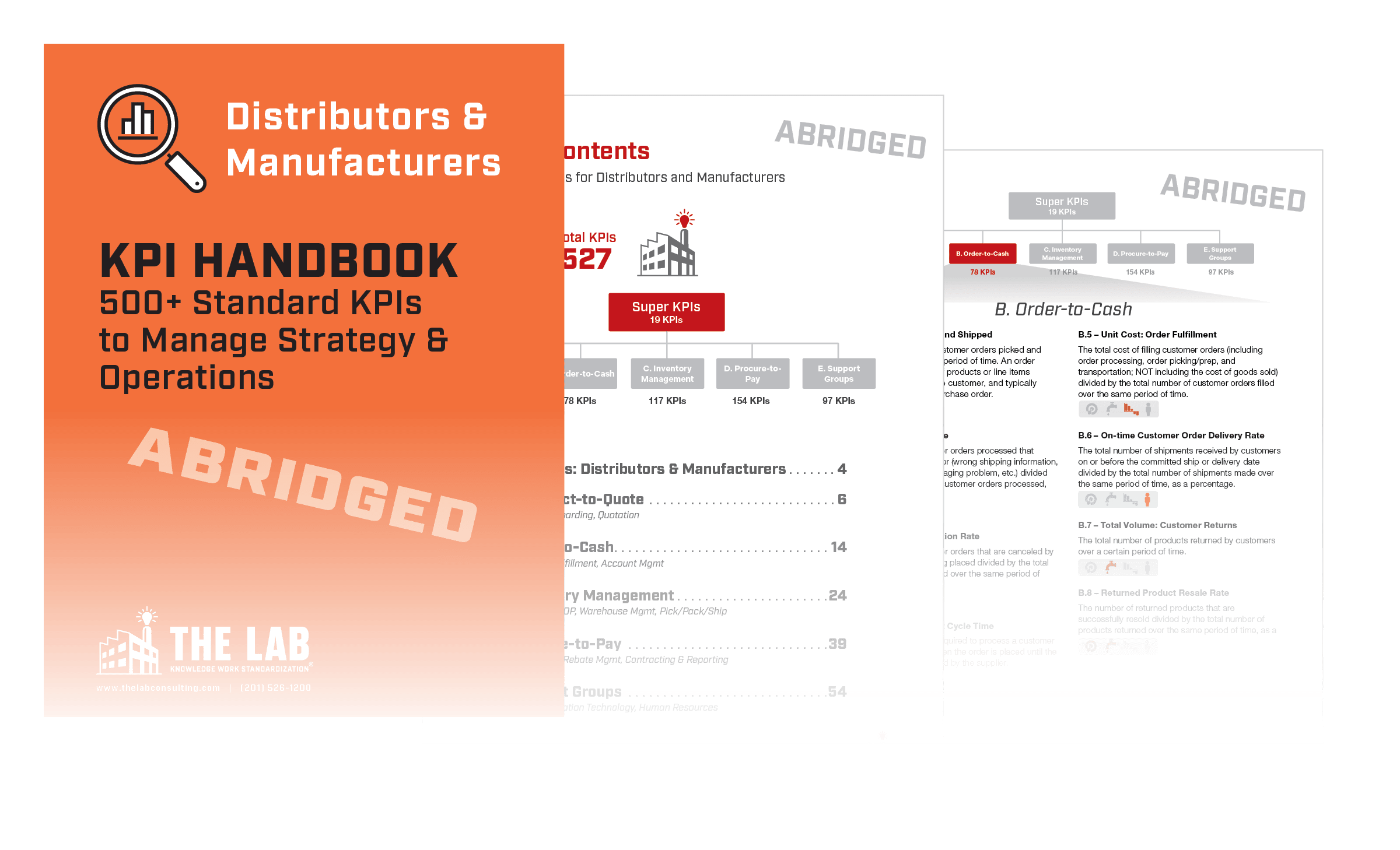

Measure What Matters

Select the KPIs—and Super KPIs™—for Your Supply Chain

The Lab’s inventory of key performance indicators (KPIs) takes the guesswork out of performance measurement. We maintain a database of over 500 standard KPIs for distributors and manufacturers. That’s a lot of KPIs (too many)! Fortunately, there’s a silver lining. There are actually a limited number of “Super KPIs” which comprise the vital few for your business.

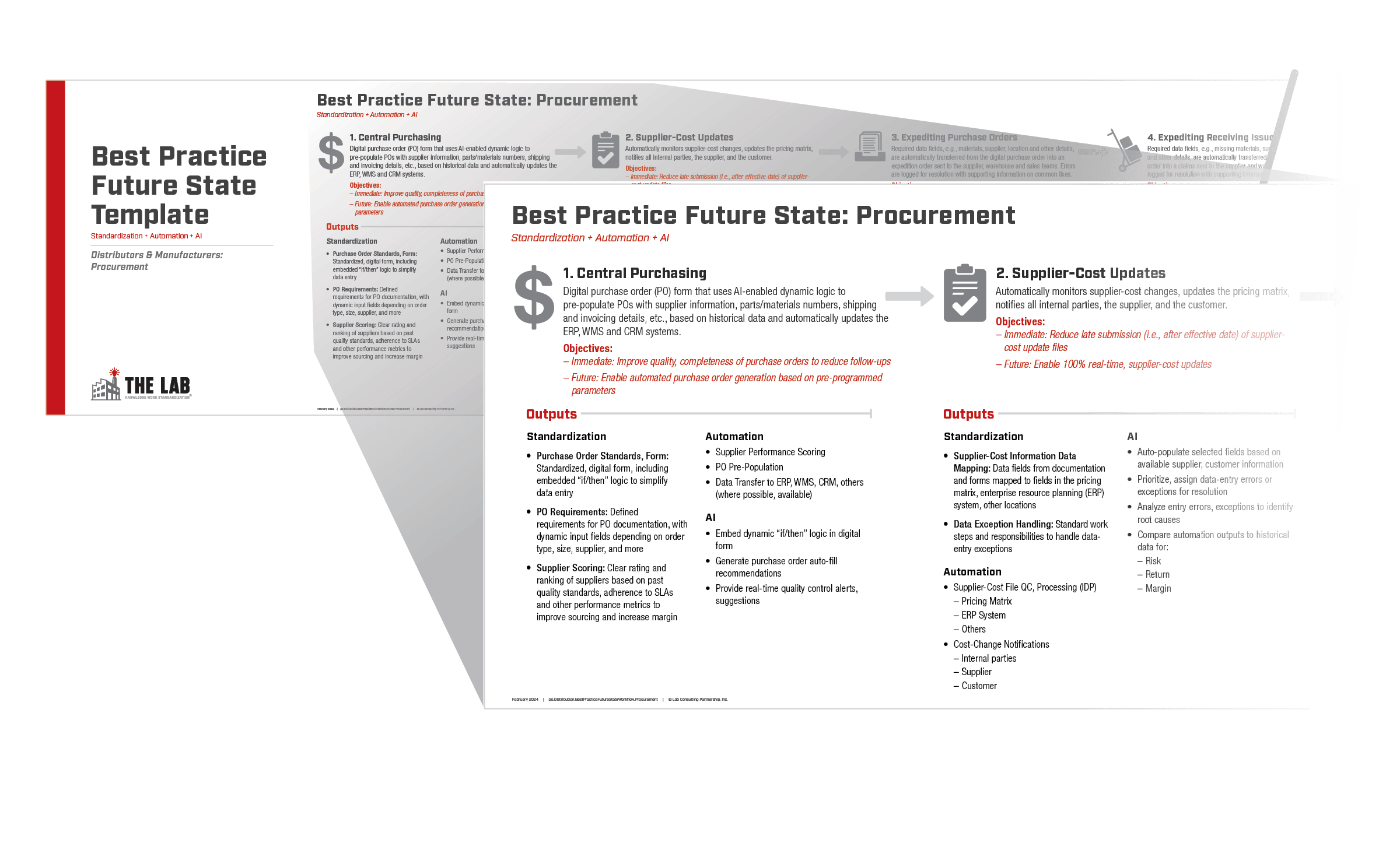

Best-Practice Future State Processes

Define the Ideal Future State for Your Business

The Lab helps clients answer the question “what should this process look like?” Our distribution and manufacturing best practice future state process models are a composite of improvements—automation, AI, analytics, and process standardization—compiled over hundreds of implementation engagements. Rapidly compare current operations against these “gold standard” industry workflows to identify gaps and design your ideal future state.

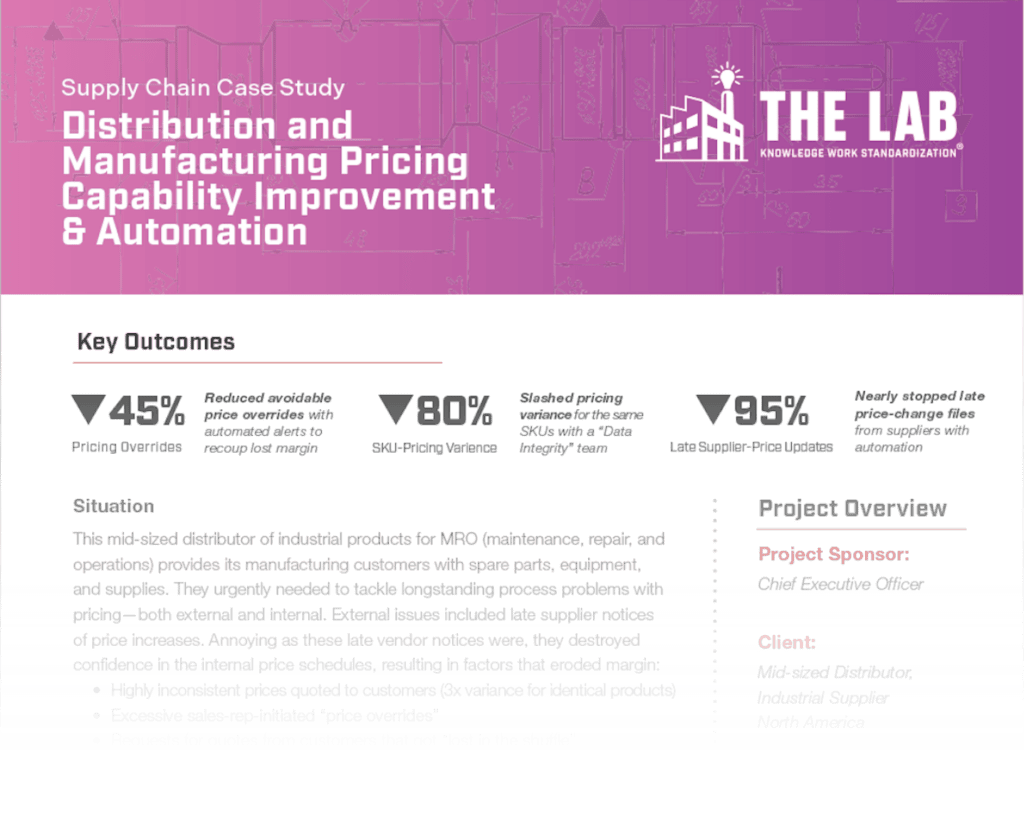

Featured Case Study

Read Real-Life Distributor & Manufacturer Client-Success Stories

Mid-Sized Distributor Stops Major Margin Erosion

Working with The Lab this distribution company standardized and automated pricing recommendations and controls to recoup millions in lost margin.

Distributors & Manufacturers: Catalogs from The Lab's Library

Preview The Lab's Distribution & Manufacturing Knowledge Base

Global Scale Standardization Strategy Expertise

Global Services Implementation Case Study

Conglomerate in 30 Countries Standardizes World-wide

By engaging The Lab this 100,000-employee giant standardized and automated field services operations to accelerate a stalled ERP implementation and generate near-term ROI.

Videos: Automation, Analytics for Distributors & Manufacturers

Watch Real-Life Knowledge Work Innovation in Action

Hear What The Lab's Distributor & Manufacturer Clients Say

“We spent years building a data warehouse but weren't seeing the promised business value or insights. The Lab helped operationalize our data.

“Without The Lab's templates, we would never have been able to map our business processes. They achieved more in 8 weeks than we did in 2 years.

“My team is tasked with harmonizing processes across 20+ countries, so it's hard to know where to even start. The Lab's taxonomies help focus our efforts.

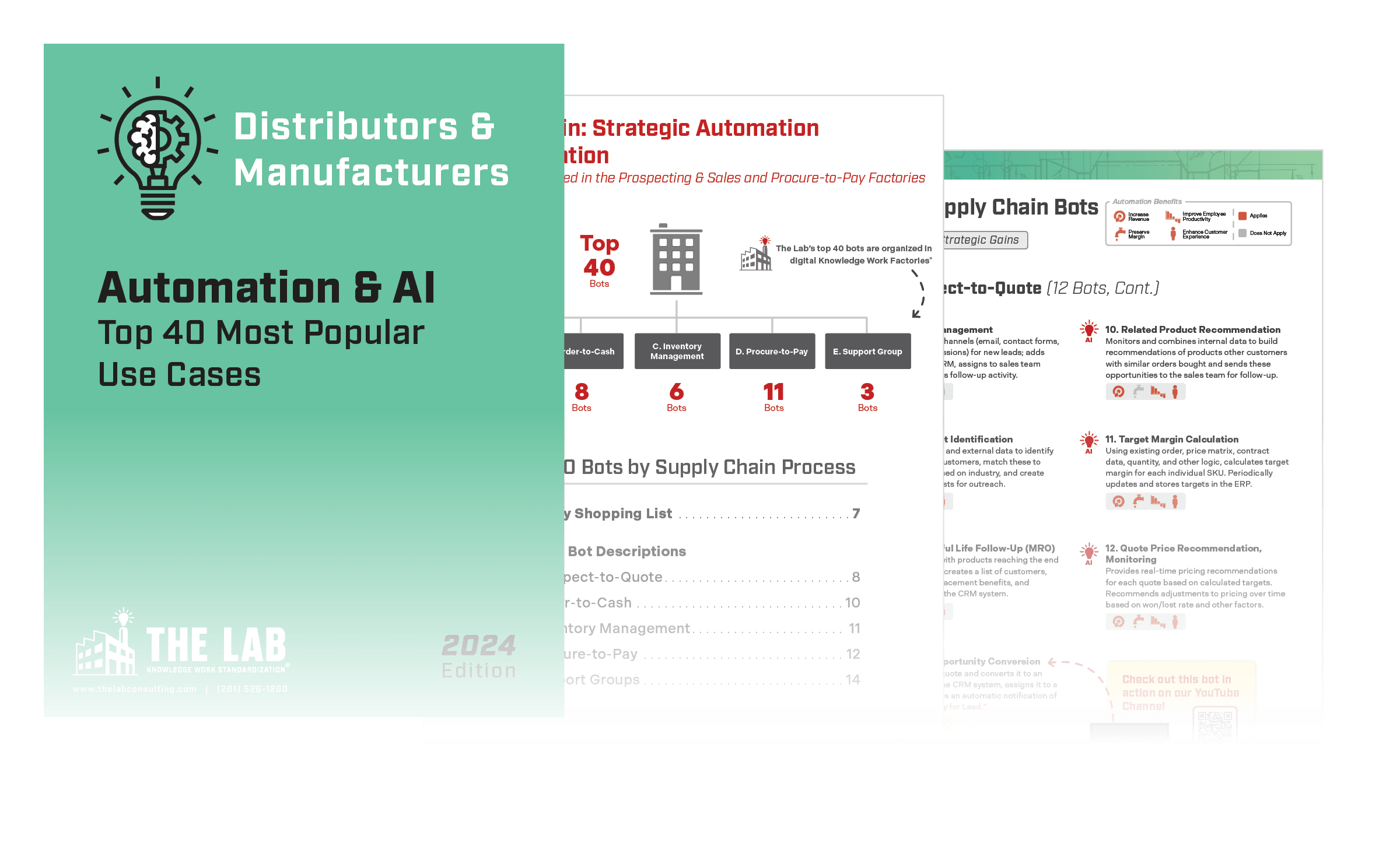

Digital & AI

Deploy the Most Valuable Automations

Quickly find the most valuable candidates and accelerate automation with The Lab’s inventory of AI-enabled supply chain bots. Lean on us to create entirely custom “humanly impossible” processes or engage us to help your organization pick from our shopping lists of previously implemented distribution and manufacturing automations.

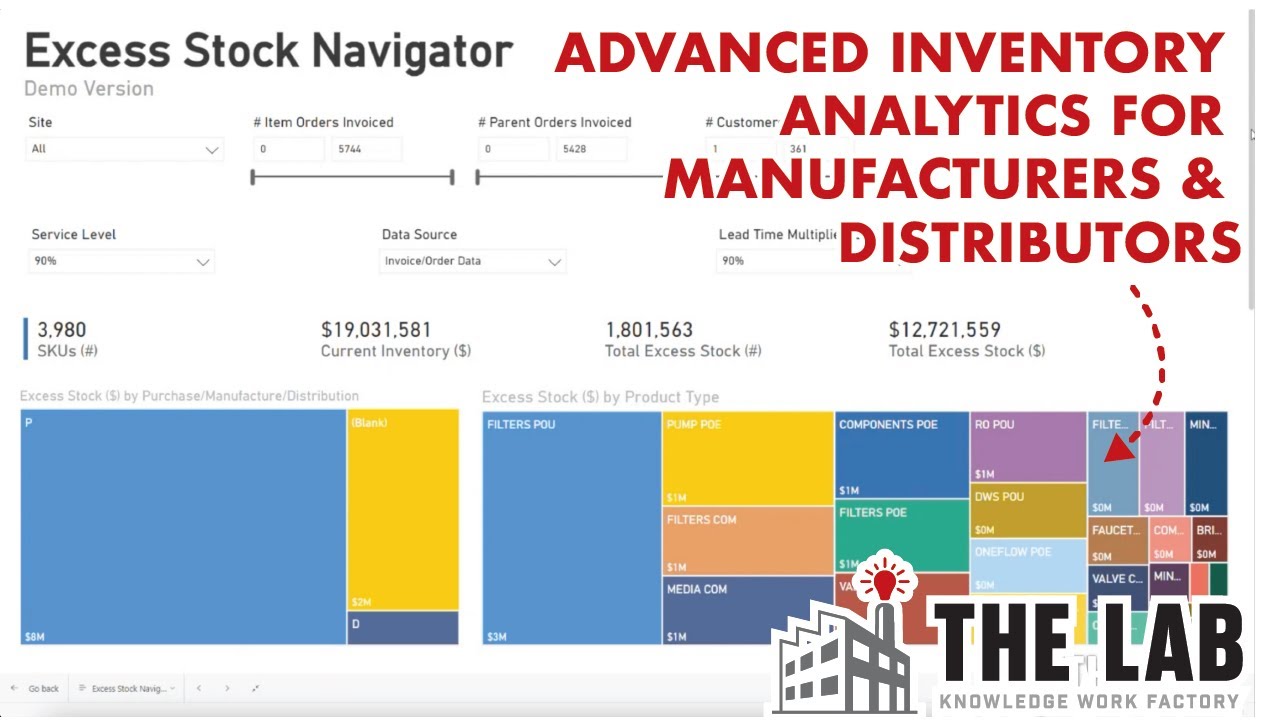

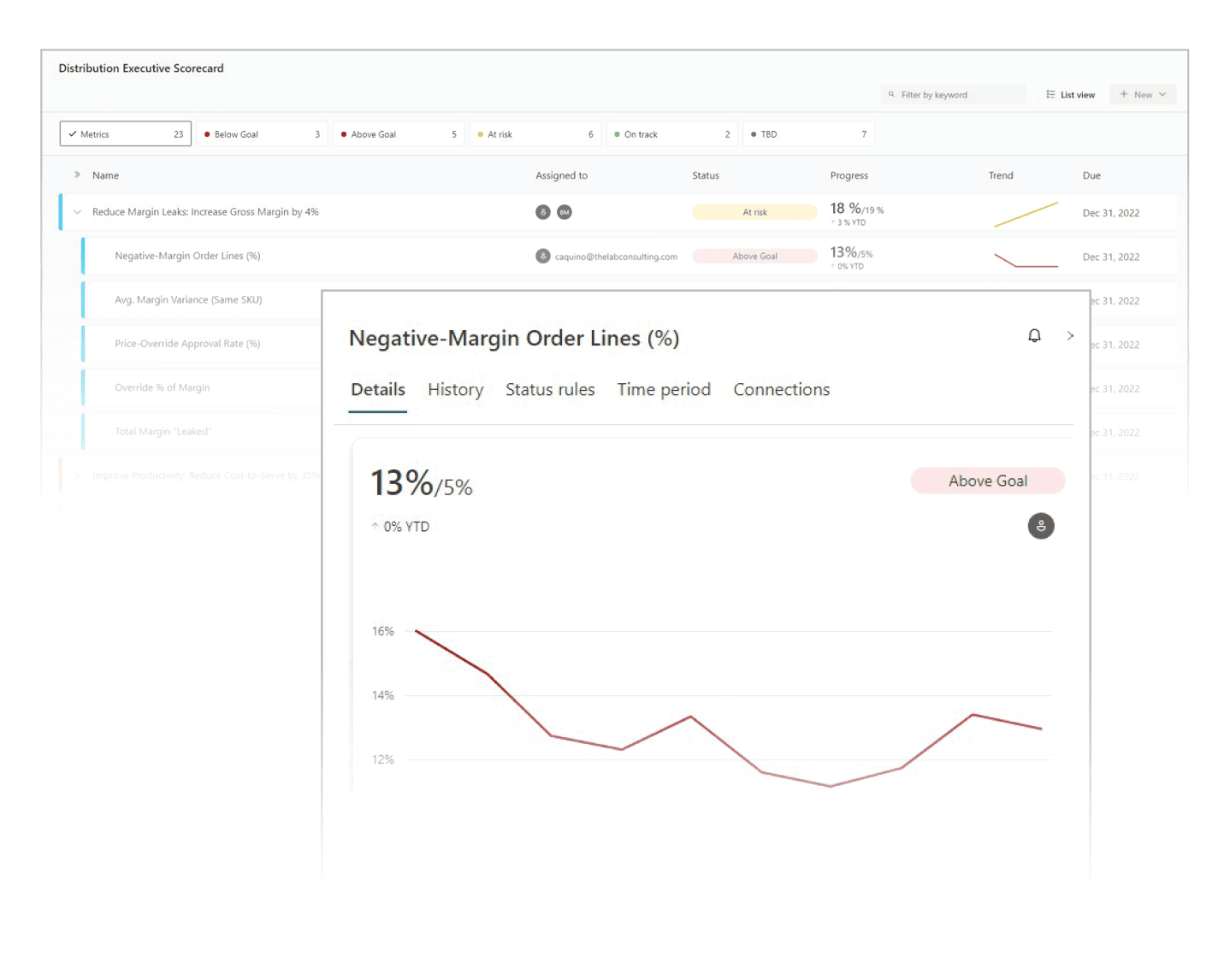

Advanced Analytics

Monitor, Manage, and Improve Performance

Create a "single source of truth" for managing performance by selecting standard KPIs and connecting your existing data sources to The Lab's standard data models.

Executive Super KPI™ Dashboard

Summarizes the vital few KPIs—usually ~20—you need to manage your business. A single, fully automated dashboard for executive-level measurement across your distribution or manufacturing organization.

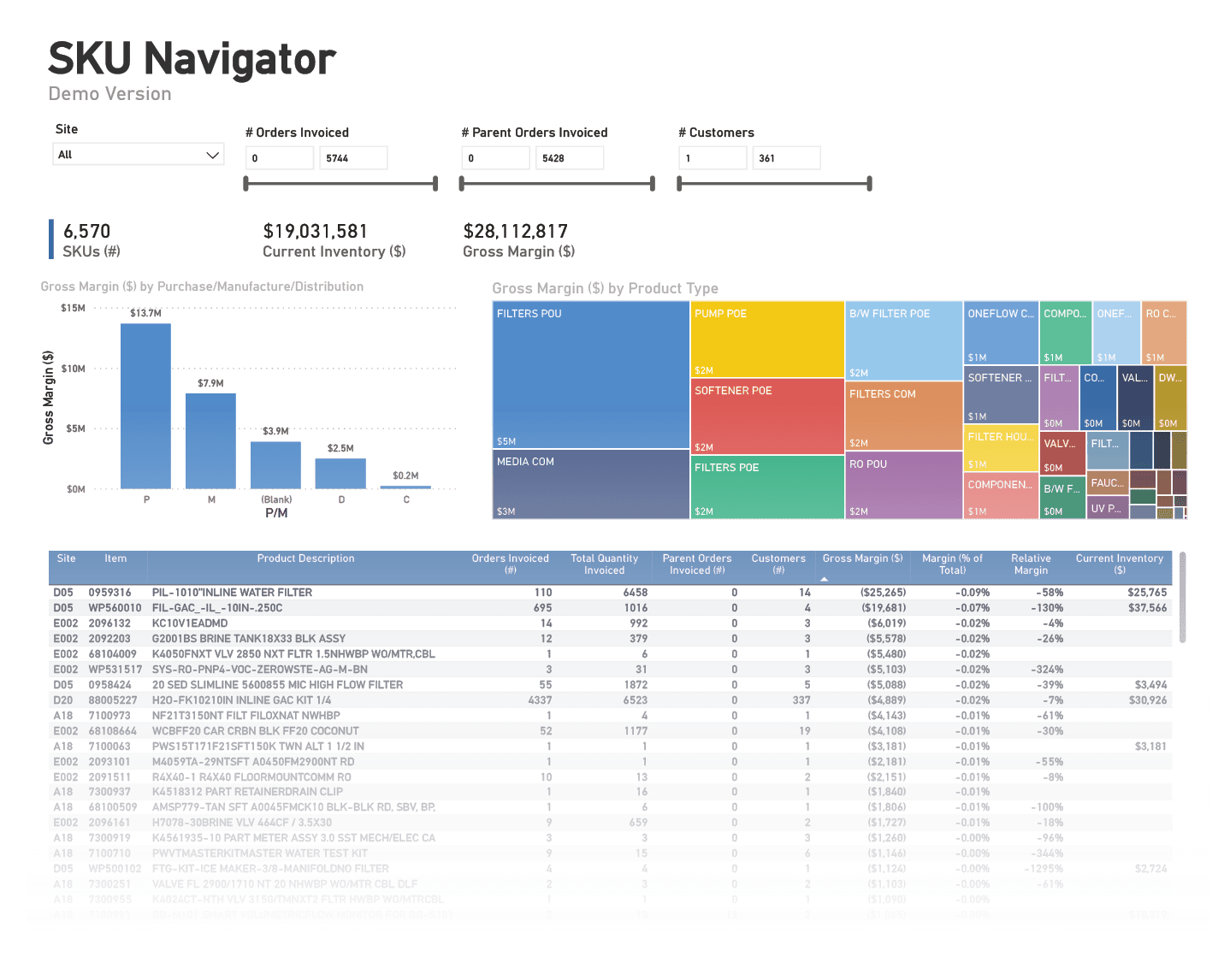

SKU Navigator

Instantly visualizes product movement and profitability by SKU, including volumes, inventory levels, and gross margin. Supplement your existing ERP and WMS reporting with data science to find more insights and automate actions.