Process Map Your 3PL or 4PL Logistics Operations in 6 to 8 Weeks

From Receiving Inventory Through Reverse Logistics/Returns, Learn How to Unlock the Value in Every Step of Your Logistics Process

Logistics operations—whether of the transactional third-party logistics or 3PL variety or overarching fourth-party logistics or 4PL kind—are all about achieving numerous goals. These include:

• Providing seamless supply-chain services (including managing several)

• Reducing costs and inefficiencies wherever possible and practicable

• Delivering superior service to your customers

This is why logistics executives should always begin their strategic-improvement and/or operations-streamlining initiatives with end-to-end or E2E process mapping of their current-state operations.

As should be obvious, you can’t design and execute the ideal future state without deep, detailed visibility into your 3PL or 4PL operation’s current state. And your future state will surely include the addition, or acceleration, of technologies such as agentic AI, automation and digital workers, and advanced analytics.

This long-form explainer article will give you all of the information you need to process-map the current state of your logistics and transportation-management operation—the vital prerequisite to any continuous-improvement, AI, automation, or analytics effort.

External factors facing 3PL and 4PL companies

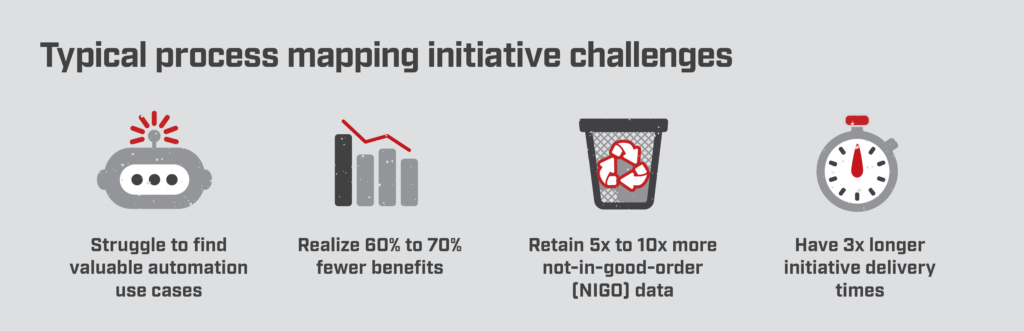

Challenges of end-to-end process mapping in logistics for 3PL and 4PL executives

Margins are notoriously razor-thin—and competition correspondingly fierce—in logistics. Thus any operational streamlining/continuous-improvement initiative is the logistics executive’s strategic imperative. They must reduce profit “leakage” across all phases while introducing agentic AI, automation, and digital workers for everything from inventory management, to pick/pack, shipping, returns/reverse logistics, and more.

As if these “baseline” challenges weren’t enough, there are external market forces to consider as well:

- Macroeconomic changes: everything from policies to tariffs

- A shifting M&A landscape

- Updates in core and ancillary technologies (which often don’t talk to each other; more on this later)

- New logistics and distribution technologies including AI

- Risk, regulatory, and compliance shifts

Clearly, it’s impossible to even consider your future state without the vital first step of process-mapping in 3PL and 4PL.

Where should C-suite logistics executives turn for process mapping?

3PL and 4PL process mapping services for logistics executive leadership: Maximize your existing technology stack

As a C-suite executive, technology or business-unit lead, or part of an internal improvement team, you know how important it is to unlock every possible opportunity for improving operational efficiency in logistics. You want to preserve (and grow) margin while improving customer service and efficiency.

The Lab Consulting can help. Our patented process-before-technology approach will help you to unlock the maximum value of your existing technology, while “layering on” new capabilities via digital workers and AI… all without a costly rip-and-replace of any of your existing (and expensive) systems, whether they’re the WMS, TMS, OMS, ERP, CRM, etc.

This article will show you the benefits and services of process-mapping for 3PL and 4PL logistics companies. We’ll show you how The Lab can help you process-map to improve operations and inventory management to prevent stockouts and overstocking, while improving demand forecasting, and more…. all in just six to eight weeks. It’s part of our specialized services for supply chain, distribution, and manufacturing leaders just like you.

Long-form executive explainer article for logistics executives

How to find the best process-mapping services for 3PL and 4PL logistics organizations

Whether your E2E or end-to-end process-mapping of your 3PL or 4PL logistics operation is performed in-house or with the help of an external consulting partner such as The Lab, this initiative will help you to:

- Scrutinize

- Analyze

- Visualize

- Spotlight process-improvement opportunities

- Find wasted effort and/or resources

- Measure and track KPIs

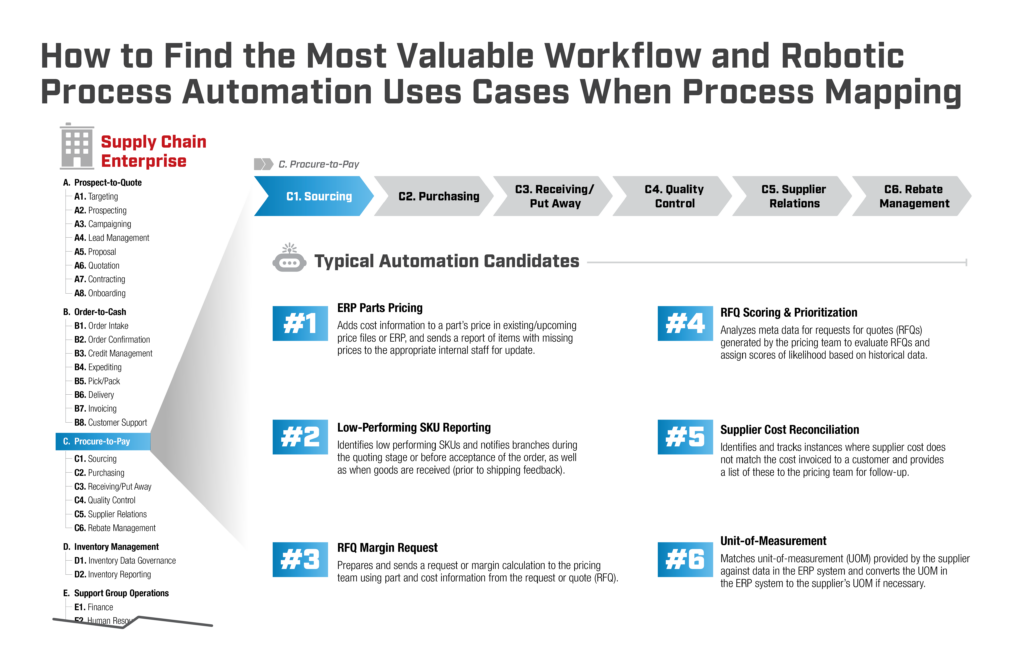

- Uncover opportunities to introduce AI and automation in logistics

—across all of your existing logistics workflows. You’ll pave the way toward a more-valuable future state in which you can maximize operational performance. So the mapping of your wall-to-wall cross-functional operating procedures is the essential first step on your transformation roadmap. You’ll be able to:

- Reduce costs

- Maximize the value of your existing technology stack and investment

- Improve customer service\

- Increase enterprise value

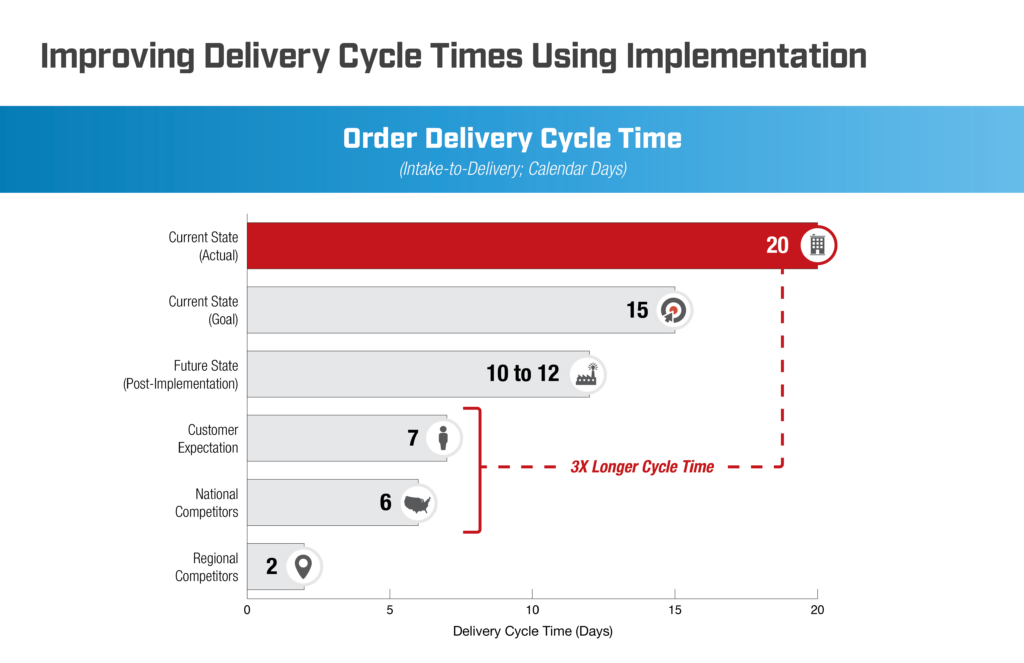

This long-form explainer article about process mapping for 3PL and 4PL will show you, step-by-step, how to process-map your operations. You’ll see which tools to use, and which traps to side-step. You’ll see how you can, for example, reduce pricing variance and overrides, and boost strategic KPIs by full quartiles, in under 12 months. That’s because, at The Lab, we’ve been helping logistics leaders just like you for more than three decades, with all of the learnings captured and catalogued in our unique Knowledge Base of client-engagement IP which is easily and cost-effectively transferrable to your company and its situation.

Process-improvement catalogs for 3PL and 4PL

The Lab’s Knowledge Base for 3PL and 4PL Operations

3PL/4PL process mapping, defined

What is the definition of process mapping for logistics?

The definition of process mapping in logistics for 3PL and 4PL operations means visually depicting your end-to-end and wall-to-wall workflows from start to finish. These can be represented as a diagram, a flow-chart, or map.

By showing what is currently being performed, it also reveals what can be improved.

A good process map for logistics will break down complex processes into simpler constituent components and steps. This increases visibility while adding more opportunity for improvement.

How-to process map (step-by-step)

What are the 3 stages of process mapping for logistics for 3PL and 4PL?

Despite our teaser of “six to eight weeks” at the top of this article, know that, when performed via tradtional methods (i.e., without the benefit of The Lab’s template-ized Knowledge Base), it can typically take logistics companies months, or even years, to process-map their organizations.

While the drafting/drawing of the maps themselves is the easy part, the harder part comes first. That’s the prep.

Overall, however, E2E process mapping for 3PL and 4PL can be broken down into three different steps.

3PL/4PL Process Mapping Step 1: Strategic planning

Typically, this step takes 3PL/4PL logistics teams anywhere from three to 18 months to complete. It includes:

- Detecting an organization-wide (or business-unit-wide) issue which requires a remedy

- Finding a project sponsor for the process mapping in the C-suite

- Defining the process-mapping project’s desired strategic outcome

- Charting a benefit-heavy, cross-functional scope of the effort

- Gaining consensus: Departmental and organizational buy-in

3PL/4PL Process Mapping Step 2: Process mapping and subsequent analysis

Working with The Lab, this vital step can be accomplished in six to eight weeks and includes:

- Gathering all existing SOPs and procedures, even if they’re dated

- Making an inventory of all systems in use

- Listing the types of data for each of the above systems

- Subject-matter expert or SME interviews

- Creating visual documentation of specific tasks, down to the 1- to 5-minute level of detail

- Holding a map fair to gather more improvements from across the different teams and individual contributors

- Creating a catalog and taxonomy of identified improvements that can be implemented in the future state

- Draft the business case and plan for the transformation itself

3PL/4PL Process Mapping Step 3: Implementation of transformation and identified improvements

The implementation typically takes anywhere from three to 12 months and includes:

- Creating and populating the appropriate implementation and support teams

- Standardization of business processes

- Reducing/eliminating “NIGO” or “not-in-good-order” processes that are wasteful and/or redundant

- Improving the quality of the data

- Adding AI, automation, digital workers, and advanced analytics and automated reporting

- Using KPIs to sustain the effort and ensure progress

Internal process mapping for 3PL and 4PL vs. external process mapping

Should you attempt process mapping of your 3PL or 4PL logistics operation on your own, or should you consult with outside experts?

As part of a large-scale process-improvement initiative—or during an M&A event or bringing in new major systems—the biggest 3PL and 4PL operators in North America typically turn to outside consulting firms for process mapping. Despite their size, they generally lack a mature internal team that can devote itself to E2E organization-wide process mapping.

Similarly, nearly three-quarters of mid-sized logistics-outsourcing firms, 3PL and 4PL alike, also lack internal process-mapping capabilities. They don’t have the teams or the talent, in-house, to perform process mapping for logistics in 3PL and 4PL.

Process Mapping Resources

Can your internal improvement teams and Lean Six Sigma Black Belts perform process mapping for 3PL or 4PL logistics?

If your 3PL or 4PL operation includes a mature internal-improvement ability, then you likely have a lot of the talent on-hand for process mapping; rarely will you find these skills in, say, your IT shop.

As a start, seek out those individuals with titles such as Process Engineer or Business Analyst. Of course, as your needs grow, the best choice for process mapping for 3PL/4PL is actual data scientists with process experience; they can then assume the traditional role of Business Analyst.

Process Mapping Resources (Part 2)

Where can you find process-mapping consultants for 3PL and 4PL?

It’s often more effective, not to mention substantially faster, to engage the services of a process-mapping specialist consultancy such as The Lab. With The Lab as your partner, you can offload all of the heavy lifting to us. We will:

• Run the process-mapping project for 3PL/4PL

• Create the actual current-state process maps

• Employ teaching methods honed across hundreds of engagements over more than 30 years

All those decades’ worth of process-mapping expertise have been transformed into standardized tools, templates, best practices, KPIs, and even automation code, to accelerate process-mapping for 3PL and 4PL. As noted earlier, all of that captured IP is part of our exclusive Knowledge Base.

Software for 3PL/4PL process mapping: Top platforms to use

What are the best tools for process mapping 3PL or 4PL operations?

Software and tools for process-mapping your 3PL or 4PL logistics operation from end-to-end range from the basic/old-school to the modern/digital. They include:

Whiteboards

Yes, whiteboards are a common tool for process mapping in logistics, whether for 3PL or 4PL:

- They’re fast. You can sketch out a summary in minutes.

- They’re well-suited to group meetings.

Brown paper rolls

Brown or white “butcher paper” rolls bring their own advantages to process mapping of 3PL or 4PL logistics:

- They’re big. Mount them on a wall, and pepper them with post-it notes.

- They’re often the go-to choice of traditional process-mapping consultants for 4PL or 3PL logistics operations.

IBM Blueworks

This cloud-based software platform allows for process mapping for 3PL and 4PL:

- It’s proprietary to IBM.

- It’s not as popular or ubiquitous as the next tool on our list…

Microsoft Visio

You have Microsoft. So you have Visio. This is the 600-pound gorilla of process mapping software:

- It’s been the world’s most popular platform of its type for more than a decade.

- It’s easy to install, care of MS Office 365.

Signavio

This can also be used for process mapping in 3PL and 4PL:

- It’s cloud-based.

- It’s a reasonable alternative to Visio.

How do you choose the best consultancy for 3PL and 4PL process mapping?

Process-mapping services for 3PL and 4PL logistics executives from The Lab

Traditional process-mapping methods for 3PL and 4PL are rife with shortcomings, pitfalls, and delays. The Lab’s unique approach, by contrast, eliminates all of those shortcoming by providing:

- More benefits for 3PL and 4PL leaders and teams. When your get your 3PL or 4PL operation process-mapped by The Lab, you’ll simultaneously be able to gauge the capacity requirements for each department and business process. This paves the path forward for a detailed benefits case for implementation.

- Faster analysis for 3PL/4PL. When your 3PL/4PL team works with The Lab, your SMEs will only need to devote about an hour a week to the process-mapping effort, across a six- to eight-week span. It’s a minimal-impact use of their time.

- Get more 3PL/4PL process-mapping benefits. To help you identify opportunities for introducing AI and automation/digital workers, control points, and eliminating avoidable rework, you’ll get processes mapped from end-to-end, all the way down to the individual activity level of detail.

- Best practice implementation opportunity. By benchmarking your 3PL/4PL’s operations against peer best practices, The Lab can pinpoint competitive gaps, helping to craft an improved future state for your operations.

Check out The Lab’s process-map catalog for 3PL/4Pl, distributors, and manufacturers.

Best-practice process-map benchmarks for 3PL and 4PL executives

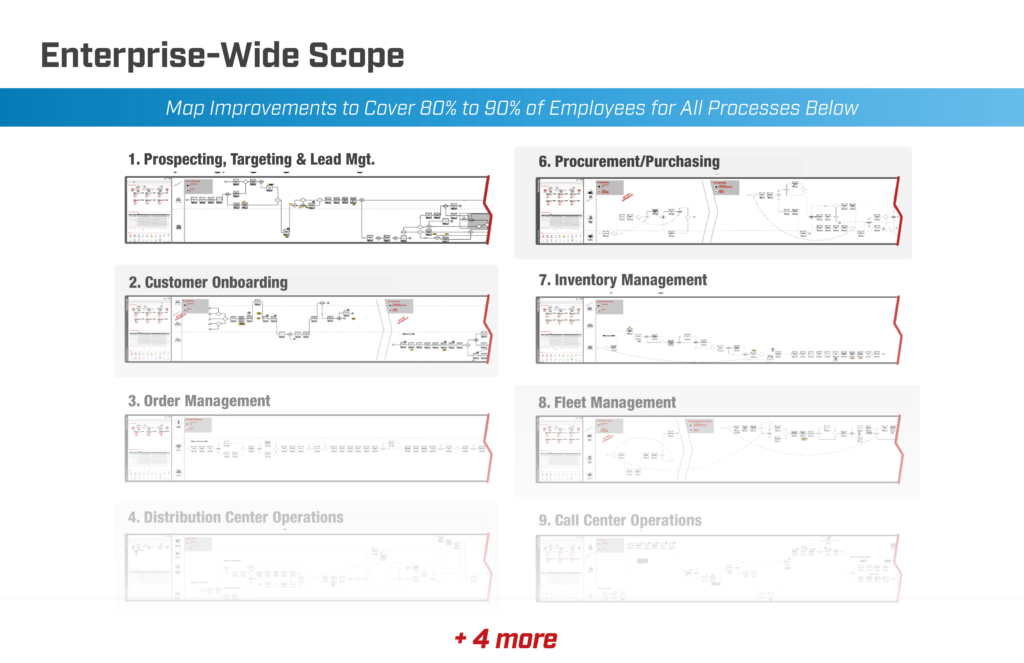

How should you scope a 3PL or 4PL process-mapping project?

Despite the obvious differences between discrete 3PL and 4PL organizations, not to mention wholesalers and other supply-chain partners, you might be surprised to learn just how similar they are. The same applies to how big they are: size doesn’t affect the similarity of 3PL/4PL companies and their brethren, whether they’re large, mid-sized, or small operators.

When viewed through the “project scoping” lens, this inherent similarity makes scoping pretty simple. For example, the process for unloading new goods into a warehouse and scanning the packing slip or WRO (warehouse receiving order) into the WMS (warehouse management system) is likely 75% similar at 3PL “A” vs. at 3PL “B.” This holds true for other 3PL/4PL processes, such as inventory management, order processing, pick/pack, and so on.

What, then, are the differences? These depend upon the way the workflows have been originally configured by the implementation teams in the core and ancillary systems used by your 3PL or 4PL organization.

Best Practice Roadmap

What are the Top 5 best practices for scoping a 3PL or 4PL process-mapping project?

When you scope out your 3PL/4PL process-mapping initiative, be sure to adhere to these best practices:

- Focus on your end to end processes across the business. For example:

- Order-to-cash all the way from order intake (confirmation, then credit management, then placement of the order) all the way through fulfillment (pick & pack, ship & track, and delivery), as well as expediting, invoicing, and collections.

- Inventory management from production operations through receipt of goods, warehouse operations (including optimizing designated storage locations, e.g., pallets, shelves, or bins), to dead-stock reporting, monitoring, and forecasting to prevent overstocking or stockouts, fleet management, and more.

- Dismantle internal silos that may exist in your 3PL or 4PL operation:

- Your process map should depict the entire customer journey, as well as the complete sales process, all back-office operations and their constituent activities, and every single regulatory/compliance checkpoint and stage-gate.

- Focus on ROI and benefits. To ensure this, ascertain that your process map spans all business functions and departments.

- Get C-level sponsorship. Without a “view from the top,” individual organizations might otherwise “opt out” of this essential initiative.

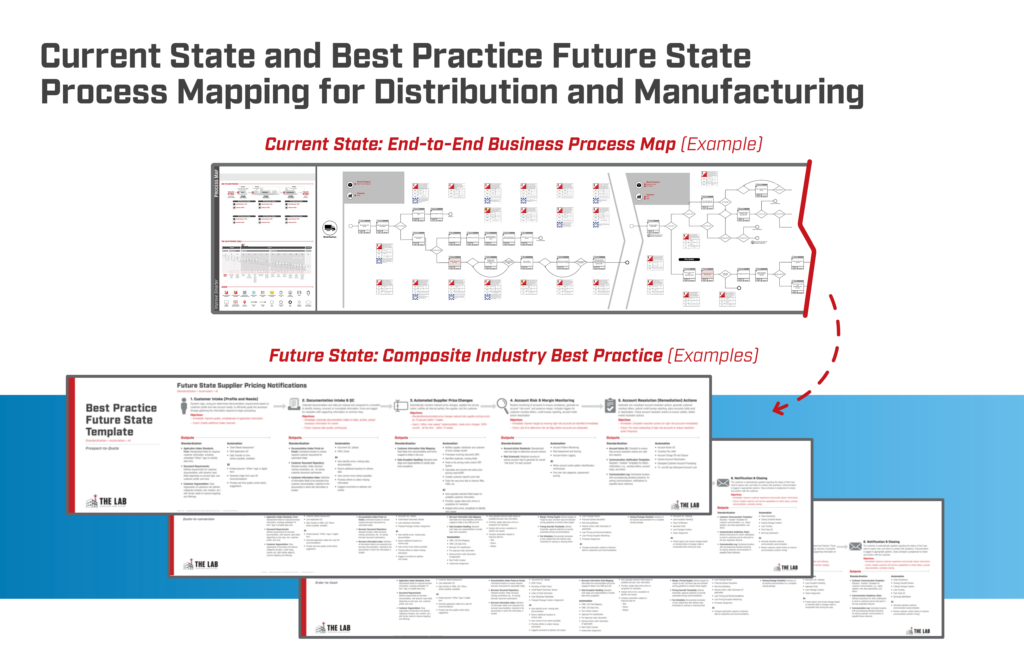

While process maps certainly vary by organization, a representative E2E process map can be seen below:

Systems Included In Process Mapping (All)

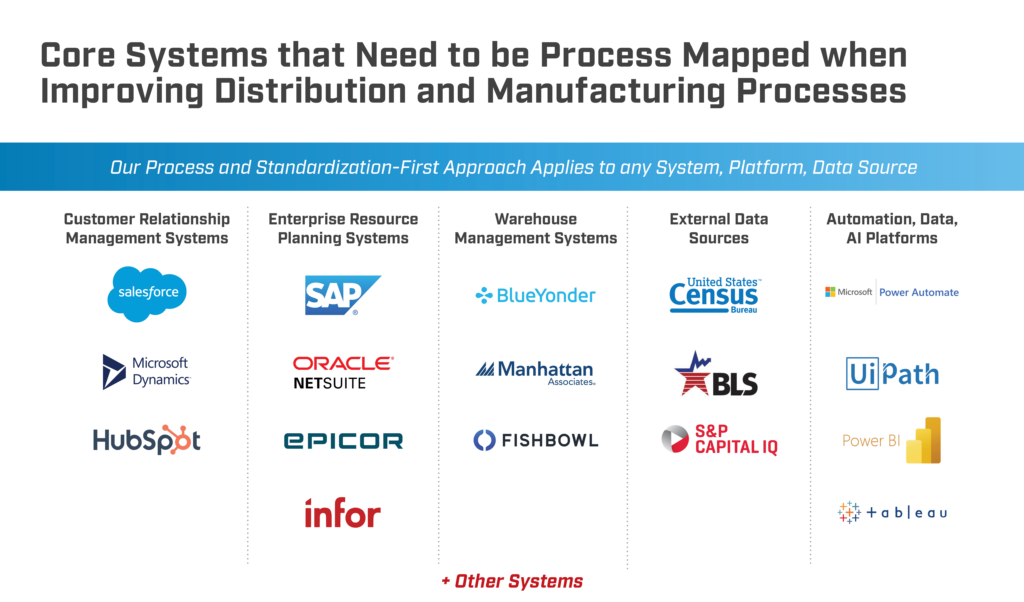

3PL/4PL process mapping should include all core logistics and ancillary systems

You’ll need to map every department… and every system you use. These include those systems which are core to logistics and supply chains:

- WMS: Warehouse management system

- TMS: Transportation management system

- OMS: Order management system

- Rate-shopping software

But don’t overlook all those ancillary systems, too, including:

- ERP: Enterprise resource planning platform

- CRM: Customer relationship management platform

- HRIS: Human resources information system

- Payment-processing system

- Data warehouse

- Others

When you include all of your systems in your process-mapping scope, you’ll get the detailed end-to-end perspective you require. Or think of it another way: If you limit your workflows to just a single system, you’ll miss out on the enterprise-wide “lift” of a wall-to-wall approach.

How The Lab performs process mapping for logistics companies of all sizes

How can you perform 3PL or 4PL process mapping in just 6 to 8 weeks?

We’ve mentioned our Knowledge Base and patented Knowledge Work Transformation™ delivery methodology a few times in this article. This standardized approach from The Lab, along with future-state templates of best practices, accelerate the delivery timeframe for us to document, analyze, and map your 3PL or 4PL business. Oh, and our process-obsessive team doesn’t hurt either!

This allows The Lab to process-map 3PL operations or 4PL enterprises in just six to eight weeks. We document all business processes:

- E2E or end-to-end

- Mapped down to the one- to five-minute activity detail level

Improvement and operational details are layered onto each map:

- Job roles

- Customer touch-points

- System usage

- Wasted or redundant effort\

- AI and automation use-cases\

- Standardization opportunities

- More

Note, too, that The Lab designed our process-mapping approach so you don’t have to “shut down your 3PL/4PL business to map that business.” For the duration of the engagement, we’ll only need one to two hours per week, per SME. We know your organization is working nonstop at full throttle; we do our best to avoid slowing down your team.

Best Practice Steps To Process Map

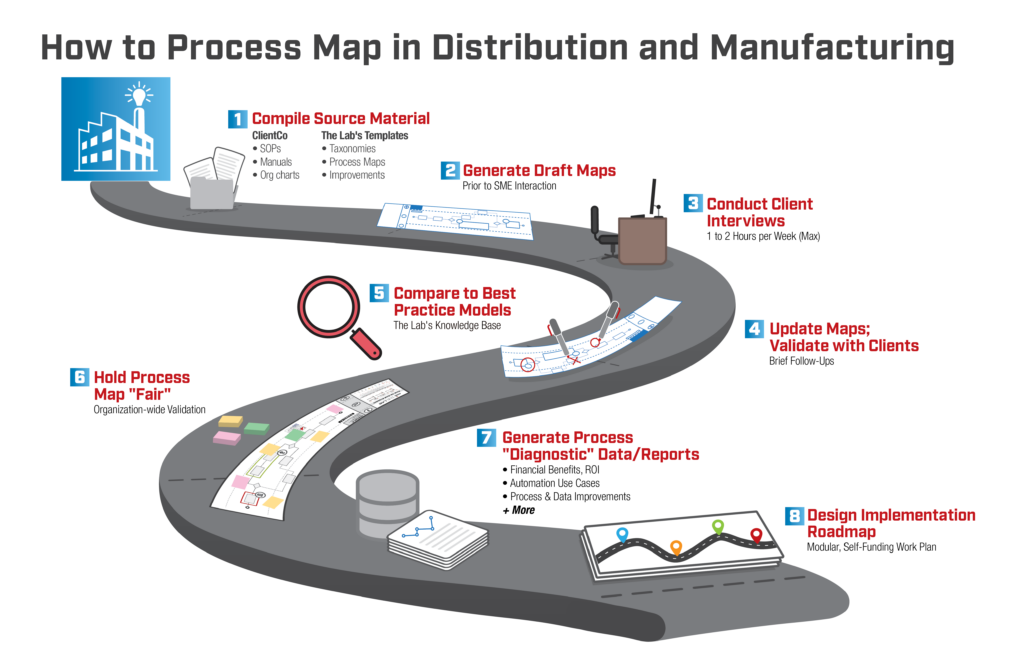

What are the 8 best practice steps for process mapping your 3PL or 4PL business?

When you engage The Lab to process-map your 3PL/4PL operation, we adhere to the following 8-step best practice methodology.

Step 1

3PL/4PL Best Practice Process-Mapping Step 1: Gather all your system data and source material, regardless of age/condition

Many of The Lab’s clients are surprised by this kick-off request of ours. When we start a 3PL or 4PL process-mapping engagement, we want you to share with us all of your existing manuals, SOPs, process procedures, and other information.

We don’t care about its age or condition; we still want it. It could be years out of date, or wildly incomplete. Doesn’t matter to us. The reason is that all of this information lets us perform research before we engage with your teams. So we’ll ask to see:

- Org charts

- SOPs

- Policy & procedure manuals

- Operational reporting, regardless of condition. We don’t care if your KPIs are in messy Excels or PowerPoint slides

But that’s not all we’ll request. The Lab will also ask that you provide us with data extracts from all of your systems. Don’t worry: We just want redacted data, without any PII (personally identifiable information) or customer-sensitive info. In fact, we don’t need (or want!) any PII data to uncover trends such as:

- Order-to-shipment cycle times

- On-time delivery rates

- Order error rates

- Incident rates

- Line-item fill-rates

- Incident resolution cycle times

- Overstock/stock-out rates

- Restock/refurbish/disposal rates

And those KPIs are just about productivity! We’ll also gather data to help improve your 3PL or 4PL operation’s sales effectiveness and gross margins.

The data we collect will be compared to the process maps; this will inform the creation of a current-state capacity model. It will also quantify the improvements for an implementation business case. Remember that, at its core, The Lab is an implementation firm.

The Lab’s industry-leading Knowledge Base contains IP and templates relevant to 3PL and 4PL operations, including:

- Process maps

- Taxonomies

- Process improvements

- AI and automation/digital workforce use-cases

- Reorganization

- KPIs

- Standardization opportunities

- Benchmarks

- Best practices

Step 2

3PL/4PL Best Practice Process-Mapping Step 2: Draw the v1 process maps

After collecting and processing all of the data mentioned in Step 1, The Lab creates the Version 1 process maps. Importantly, we do this before we confer with your SMEs, in order to be as respectful of their time as possible.

The Lab performs all of our process-mapping layouts in MS Visio. This readily available file format makes it easy to hand off the completed maps to your 3PL or 4PL business, so your teams can update them as they see fit.

Since Visio is a Microsoft product, you needn’t worry about having to onboard another vendor. And while we know our work is great, we’re also well aware that no 3PL or 4PL wants consultants hanging around forever!

Step 3

3PL/4PL Best Practice Process-Mapping Step 3: SME interviews

After completing the Version 1 process maps, it’s time for The Lab to engage with your front-line SMEs or subject-matter experts: These are the people “in the trenches” who perform the daily tasks in 3PL such as warehousing, order fulfillment, transportation, and/or overall supply-chain integration.

Using Zoom or MS Teams, we share the Version 1 process maps with them. We then ask them about the gaps we perceive in the process. We also work with them to add further details to the maps. Note that this engagement requires only an hour or two per week with the SMEs. We want to be super respectful of their time.

Step 4

3PL/4PL Best Practice Process-Mapping Step 4: Iterate and validate the process maps

Once the first round of fact-finding and process-mapping with your team is complete, we at The Lab will iterate the process maps. This spans about four weeks, using a “lather/rinse/repeat” cadence as we build out increased map detail.

In our 30-plus years of experience, we have found that no one can ever remember every single step of a process in a single sitting. That’s why we revisit them multiple times, in short bursts across several weeks. This approach, we have found, builds out the best level of detail which the 3PL/4PL organization can them improve upon.

Step 5

3PL/4PL Best Practice Process-Mapping Step 5: Compare process maps to best-practice peers

After we’ve completed drafting the current-state process maps, we’ll compare your 3PL or 4PL process maps to industry best-practice models and peers. This step is essential for creating the most valuable future state for implementation.

The Lab’s Knowledge Base and best-practice models include:

- Use-cases for automation/digital workers and agentic AI

- Benchmarks

- Best-practice process improvements

- KPIs (Key Performance Indicators)

- Job/role descriptions

- Process- and data-standardization opportunities

- Opportunities for reorg

Step 6

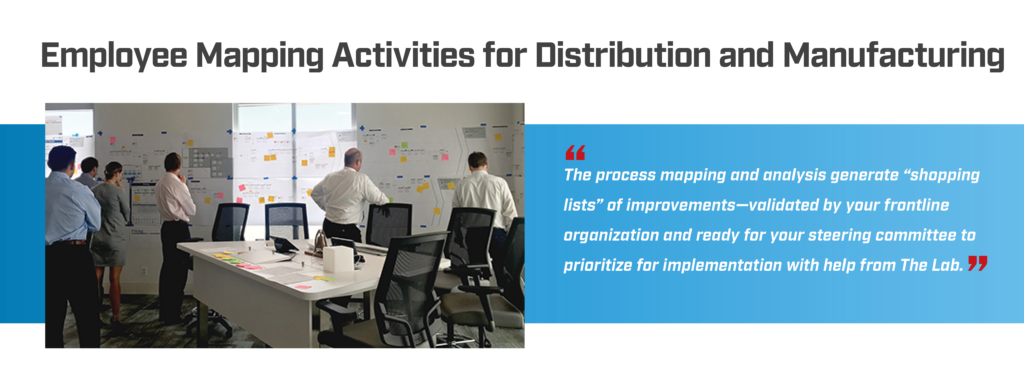

3PL/4PL Best Practice Process-Mapping Step 6: Hold an org-wide Process Map Fair

Now that all of the initial activities of process-mapping, generation, and validation have been completed, it’s time for The Lab to display large-scale printed versions of the process maps for the entire 3PL or 4PL organization to review. These on-site “Map Fairs” are conducted in-person; they’re typically held within common areas inside the 3PL or 4PL organization’s headquarters. This makes it easy for your entire supply-chain/logistics staff to visit the Map Fair at their leisure across a two-day period.

The Map Fair empowers your staff to add contributions anonymously (if they so choose), further validating the process fact-base which the 3PL/4PL organization has helped to create. The on-site Map Fair socializes the findings of the process-mapping effort, while preparing the entire organization for upcoming process changes. Thus the Map Fair creates buy-in across your 3PL/4PL organization, because everyone has had an opportunity to contribute their input.

During the Map Fair, team members are encouraged to mark up the map as they see fit with color-coded Post-it notes:

- Green means: “I strongly agree with this.”

- Yellow means: “I think that there’s missing information” or “I believe that there’s an additional process step or improvement which should be added here.”

- Red means: “I strongly disagree with this.”

After the Process Map Fair has concluded, The Lab will analyze all of the new Post-it contributions, reconciling them into the final version of the workflows. At this point, the 3PL/4PL process maps are considered to be final—and ready to put to use (see below):

Step 7

3PL/4PL Best Practice Process-Mapping Step 7: Create the staffing capacity model and diagnostic reports from process data

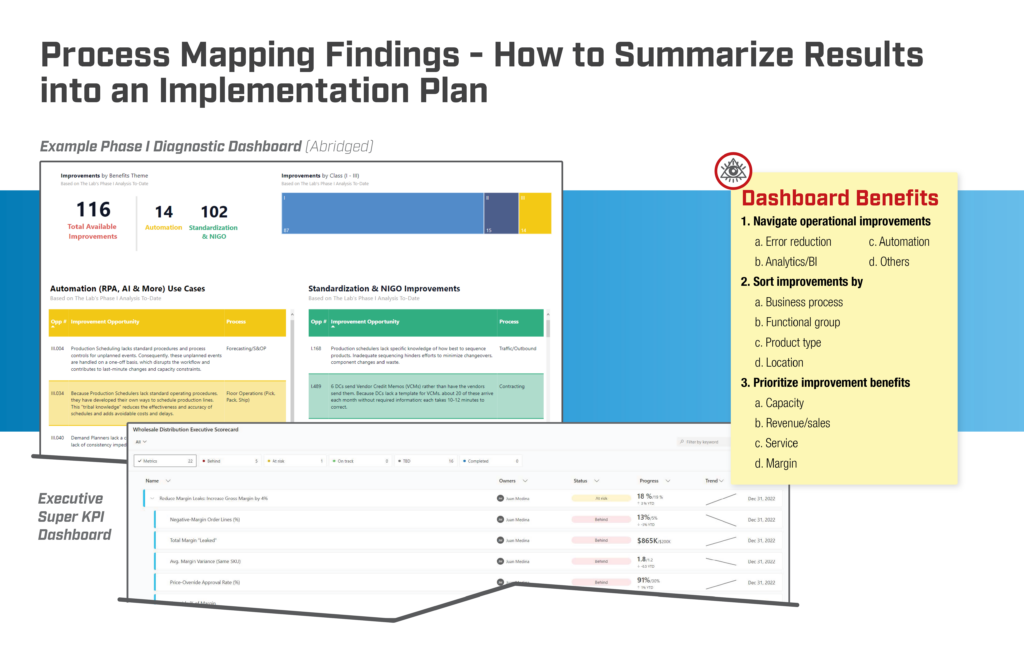

Thanks to the two-day Map Fair’s final validation, analysis, and buy-in, there will be literally hundreds of available improvements. Here are the kinds of improvement opportunities we typically see among 3PL and 4PL organizations:

- Roughly 150 – 250 opportunities for process and data standardization

- Roughly 100 – 200 use-cases for AI and automation/onboarding of digital workers

- Roughly 50 – 100 use-cases for advanced analytics

The Lab will then import these improvement opportunities into a centralized, navigable database. We also create an MS Power BI dashboard, which 3PL/4PL leaders can use to visualize, prioritize, and then plan which of those opportunities should be implemented—and in which order.

Each improvement opportunity and use-case is then quantified in terms of its financial benefits, time savings, customer-experience lift, technology under-utilization to remedy, and more. After The Lab compiles and quantifies the individual improvements, we’ll then create a comprehensive organization capacity model for your 3PL/4PL business. This will act as your baseline for calculating the business case and corresponding value of implementation, work plans, and modules.

The outputs include:

- Financial benefits & ROI

- AI and digital workforce/RPA automation use-cases

- Process & data improvements

- Others

Step 8

3PL/4PL Best Practice Process-Mapping Step 8: Draft the schedule for implementation

No matter how complex your 3PL or 4PL logistics operation may be, you simply can’t implement every single identified improvement in one shot. Of course, it’s tempting. But it’s not likely to succeed.

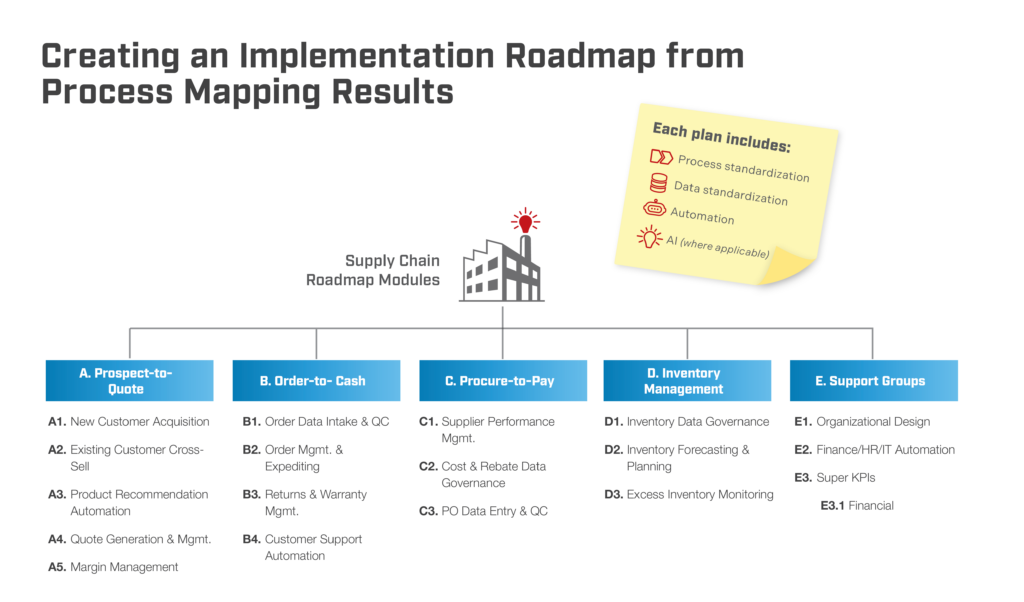

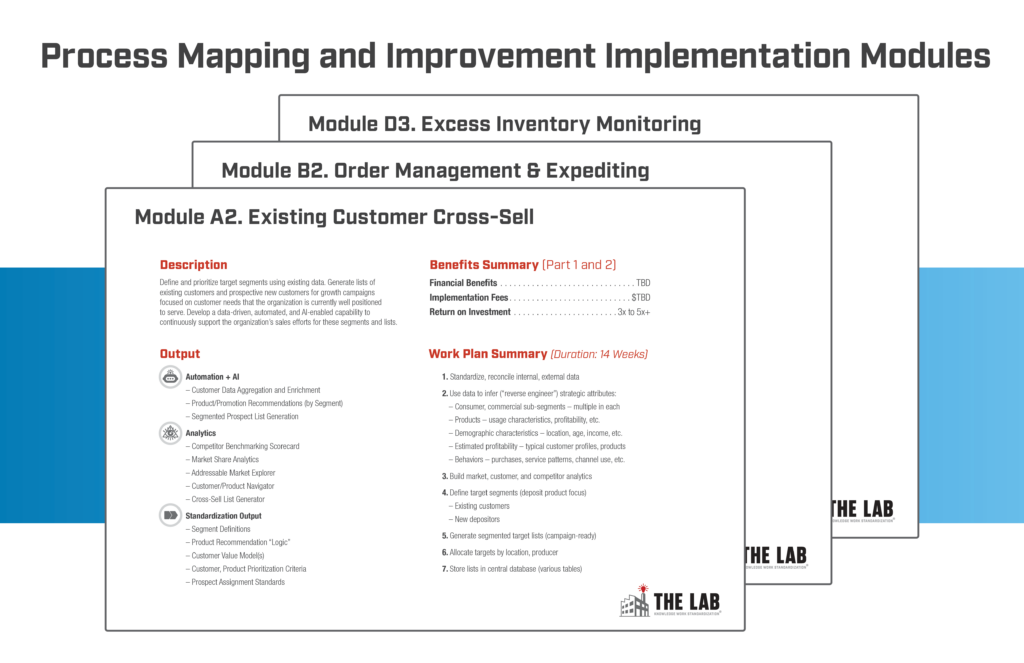

Over the decades, we at The Lab have discovered that our 3PL and 4PL clients are much better off taking on achievable “bite-sized” modular implementation plans which line up with a short-/mid-/long-term strategy.

That’s because we’ve also learned that a continuous-improvement approach will always deliver more longer-term benefits than would a short-term, big-bang, all-in-one attempt. Working with our 3PL/4PL client, The Lab helps to implement in the beginning; by the end, the 3PL/4PL clients are able to implement on their own.

Outputs from this step include:

- A self-funding modular work plan for 3PL/4PL

- Schedule divided by business-calendar quarters

- Optimal mix of process improvement, AI, digital worker onboarding, RPA automation, and KPI-based analytics

- Jointly designed by The Lab and the 3PL/4PL’s executive steering committee to meet the business’s strategic objectives

Despite what we just advised above, there are exceptions to the rule: Some business situations actually require an all-in-one/big-bang approach. The Lab has supported some of the world’s largest re-organizations amid these challenging circumstances, as the situations have dictated.

Top 5 Benefits to Process Mapping

What are the benefits of process mapping for 3PL and 4PL businesses?

Contact us today to book your demo

Transform your 3PL or 4PL operation

The Lab has helped 3PL and 4PL C-suite executives, business-unit and technology leads, and internal-improvement teams to map all of their organizations’ business processes and customer journeys. We’ve helped them to streamline operations, increase CX, and realize significant cost savings. We identify and implement AI, digital workforce, and RPA automation opportunities and advanced analytics. These improve process resiliency while hedging against employee turnover. Our comprehensive solutions deliver measurable results and drive success.

Ready to transform your 3PL or 4PL operation? To book your screen-sharing demo, call (201) 526-1200 or email info@thelabconsulting.com today.