End-to-end (E2E) standardization—from sourcing through production and distribution—to modernize supply chain ops

Disruptions in the distribution landscape were threatening to overwhelm the company. Costs were skyrocketing for both direct (ingredients and packaging) and indirect (MRO or maintenance, repair, and operating supply) materials alike. Despite the company’s hefty ERP and CRM investments, they’d been set up—and configured—pre-Amazon. And that was just the tip of the iceberg: While the company was still configured to serve larger, traditional consumer packaged goods (CPG) channels—wholesalers, grocery chains, and route sales distributors (such as re-stocking convenience stores)—a host of new customers and channels had arisen. These included a company-owned e-commerce site, and discount clubs, with their unique needs for bulk, palletized packaging and in-display boxes. Meanwhile, aggressive new competitors from Latin America were closing in.

Fortunately, no capital spending was needed for new core systems; the existing ones already boasted the required capacity and functionality. But the good news ended there: The data—for vendors, products, and customers—was structured for the existing distribution customers. And even so, it had lots of flaws that had developed over time. Duplicate entries, system-to system reconciliation, and poor usability of master data caused order-entry errors, reduced forecast accuracy, and disrupted customer-service delivery. The resulting “workarounds” were undocumented. Things only ran smoothly thanks to the tribal knowledge that resided solely in the heads of tenured employees who were now reaching retirement age and leaving the company.

Client Description, Project Scope, Objectives

The company is a U.S.-based family-owned maker of branded, baked goods, distributed across the North American market through both traditional CPG channels and, more recently, a direct-to-consumer (D2C) channel of growing importance.

The overall project spanned everything from customer onboarding to order intake, sourcing, production, delivery, product promotion processing, and returned goods. One of the first segments (this case study) involved a rapid update of order management, including master data (product, customer, vendor, and order master) to accommodate the growth in distribution channels that drove operational complexity.

The objectives were clear: Increase order management productivity, reduce waste (including rework, order queueing, and customer wait time), cut costs, and introduce newfound flexibility to scale up or down as needed and remain continuously competitive in a fastmoving, dynamic market space.

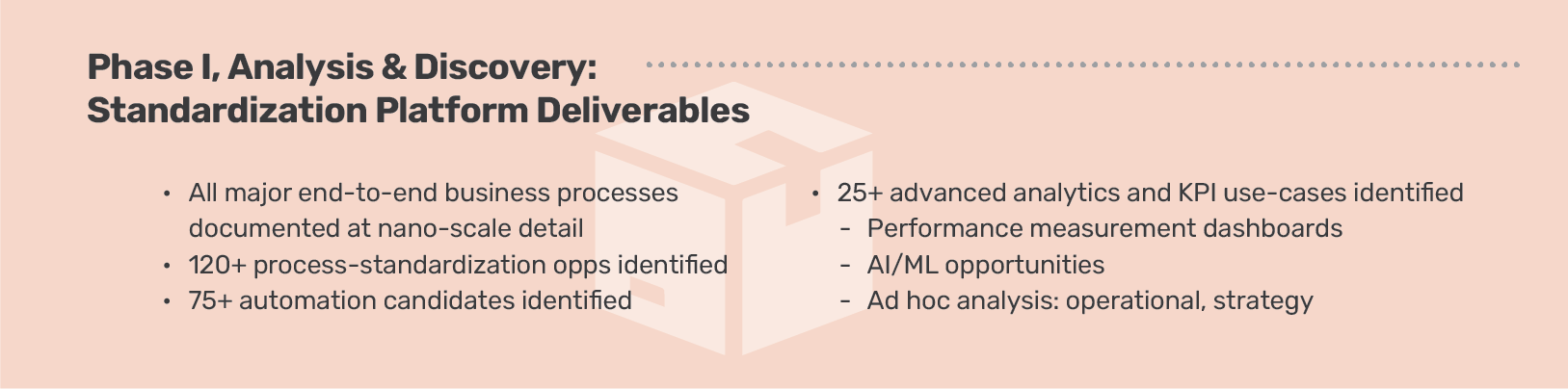

Phase I, Analysis and Discovery

An eight-week Phase I analysis covered all plant operations and employees. It delivered a self-funding, guaranteed work plan for the six-month, Phase II implementation.

Phase I Findings: The Lab’s database of supply-chain operations templates—including industry standard KPIs, process maps, benchmarks, best practices, automation “use cases” and more—enabled rapid documentation and analysis of more than 85 percent of employee work activities (approximately two minutes each), while only requiring one hour per week of any subject matter expert’s (SME’s) time. The Lab’s patented, template-based approach achieved several analytical goals:

• Accelerate business process mapping, which had been historically slow and tedious.

• Identify applicable automation and standardization improvements from The Lab’s database.

• Document gaps in existing technology utilization, such as features, functionality, and add-ins.

• Normalize application and system event log data to enable detailed reporting and benchmarking.

• Prepare business processes for AI-enablement for real-time reporting and decisions.

Coordinating and reconciling the client’s data with The Lab’s templates resulted in E2E (end-to-end) maps and improvement opportunity “inventories” that could easily be directly reviewed, refined, and validated by all company employees.

This Phase I effort delivered a self-funding business case and work plan. This launched a six-month, Phase II transformation project that implemented the recommendations and findings from Phase I.

The improved performance (detailed in the Phase II description below) was achieved with robotic process automation (RPA), workflow automation, and more effective and extensive use of the previously installed ERP and CRM platforms.

Phase II, Implementation

The six-month, self-funding, Phase II implementation effort was able to increase productivity, compress cycle times, improve customer service, and deliver cost reduction.

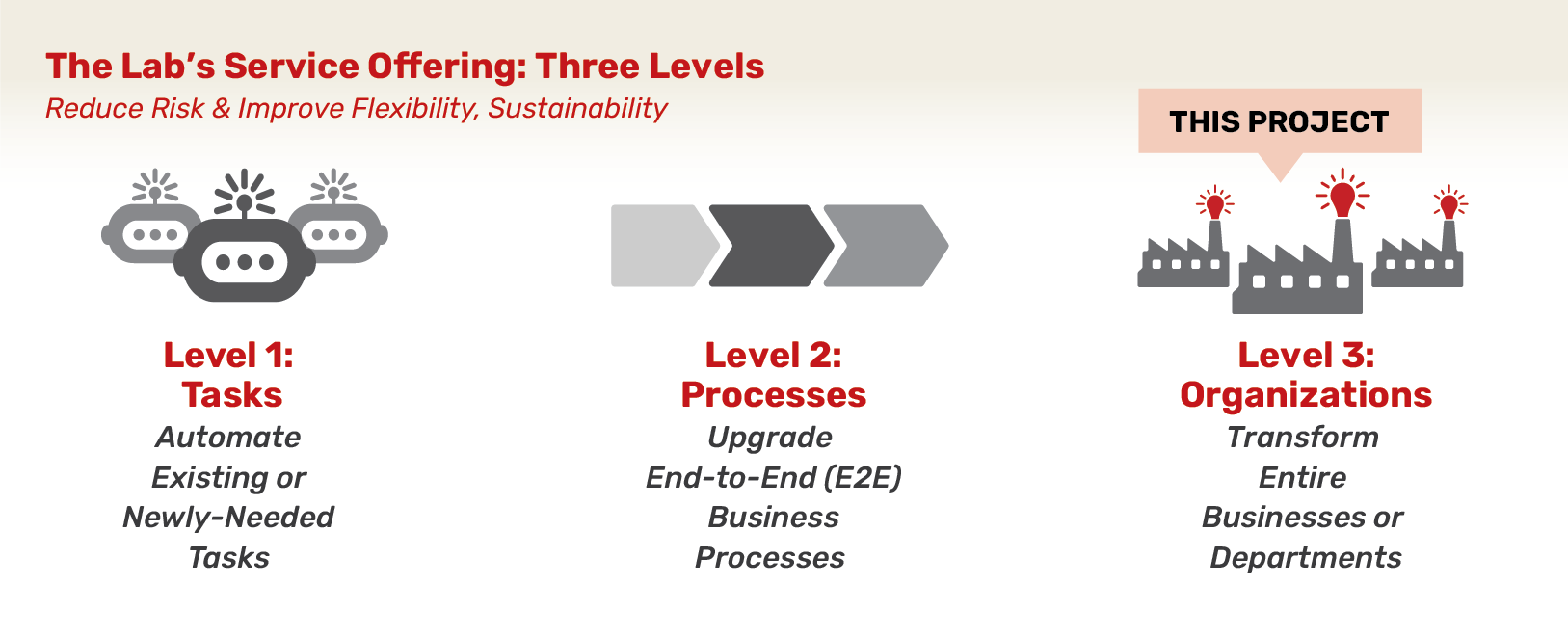

Improvement goals were established by area and/or by E2E business process, and the organizations involved could perform the work with any mix of resources they chose: internal resources, The Lab’s resources, or others. The Lab maintains a three-tiered service-offering structure (plus ongoing postimplementation support) to make this as flexible and sustainable as possible for clients:

The Lab’s improvement templates accelerated the effort. Order-entry errors were cut by half. The templates transformed the one-off activities of knowledge workers into standard work methods. The benefits of this process standardization were dramatic: On-time deliveries doubled. Cycle time fell 30 percent. Productivity rose 20 percent.

Post-Implementation Support, Sustainability & Automation

The Lab provided hassle-free, post-implementation, hourly sustainability support for this client to maintain automations, process standardization, and operational data analytics models implemented during the Phase II engagement. If the client’s team was not up-skilled enough to perform any needed automation updates, they leaned on The Lab for Tier 3-level support. If analytics dashboards required additional views or data connected, The Lab’s team was a simple phone call away.

Improvement Examples, Service and Distribution Standardization

The Lab consolidated over 200 improvements into manageable “modules” for implementation. Examples:

The Lab Makes it Easy

Organization-friendly engagement design

At The Lab, we’ve spent three decades refining every aspect of our transformation engagement model. We’ve made it easy for clients—from the C-Suite to the front line—to understand and manage the initiative:

• Minimal use of client time: One to two hours each week, maximum.

• Measurable benefits: Typical 12-month ROI is 3x to 5x.

• Pre-built templates and tools: Process maps, data models, bots, and more.

• U.S.-based, remote delivery: Nothing is ever outsourced or offshored.

Designed to reduce risk, increase success

Since 1993, The Lab has led the industry in eliminating risk for our clients. Whether your engagement involves a handful of bots or wall-to-wall transformation, we make it easy to do business with us:

• Fixed pricing and clearly defined scope

• Pre-project feasibility/value assessments at nominal cost

• Early-out checkpoints and options

• Money-back guarantees

Book your free demo

The best way to learn about The Lab’s patented Knowledge Work Standardization® approach is to book your free, no-obligation 30-minute screen-sharing demo. And you’ll get all your questions answered by our friendly experts. Simply call (201) 526-1200 or email info@thelabconsulting.com to book your demo today!