Process Mapping and Improvement for Engineering & Construction Firms

Pave the way for reduced cost, improved risk management & compliance, and increased operational efficiency

Engineering and construction or “E&C” firms fall into lots of categories, depending on their specialization and clients they serve. As an E&C executive—whether your firm’s focus is civil engineering, general contracting, mechanical engineering, design/build, or any of a host of role- or project-specific disciplines—the first step on your strategic transformation roadmap should always be process mapping.

That’s right. Process mapping is the prerequisite for every aspect of transformation in E&C, including continuous improvement, the introduction of digital workers (i.e., automation), AI, and advanced analytics.

A reasonable question to ask is “Why?” There are actually numerous reasons that process mapping and improvement are essential to any E&C executive’s agenda:

- Inefficiencies abound. One-off work methods and other un-standardized (or under-standardized) activities create inefficiencies of up to 30 percent. How can you transform your engineering and/or construction business in the face of such bottlenecks? Process mapping lets you find and eliminate them.

- Regulatory changes disrupt E&C. Whether it’s the latest OSHA safety mandates, cybersecurity-compliance regulations for government contractors, stringent new worker-classification rules, and the on-again/off-again regulations for sustainability, you need to accurately map all end-to-end processes in your engineering or construction firm to keep pace and maintain compliance.

- Technology marches on. You don’t need us to tell you how many systems and technologies your E&C firm relies upon, from CAD platforms to project-management systems, to field and site technologies, not to mention the slew of other daily systems your firm relies upon. Are you maxxing out your technology investment? Are systems going under-utilized? Are you paying for tech that you don’t need? Count on process mapping to spotlight these issues.

- Never count out the competition. Just as your E&C firm must adapt to keep pace with all of the above, so do your competitors—both existing and incipient. There’s never time to rest on your laurels; process mapping can help you effectively disrupt the disruptors, helping you to retain—and gain—market share.

But why should process mapping come first for any E&C organization? Simply put, you can’t improve until you have a detailed picture of your as-is processes. You can’t improve what you don’t understand, let alone compare it to proven best practice. So things like AI, advanced analytics, and onboarding digital workers must wait until you have your current-state end-to-end or “E2E” process map in hand.

What are the technology improvements of process mapping for E&C

Overview of process mapping and improvement for engineering & construction firms

This long-form explainer article from The Lab is geared toward E&C firms’ executives, business-unit and technology leaders, and internal improvement teams. It will show you real-world examples of process mapping and improvement in engineering and construction. It will demonstrate how The Lab can help your E&C firm, regardless of its specialization, to sell more engagements and follow-on work, improve operational efficiency and compliance, and increase margins…all in the short term.

That’s because we know that you’re always searching for ways to increase profits, revenue, and overall enterprise value. Consider, for example, the CEO of a firm like yours whom The Lab recently helped to:

- Increase billable hours more than 10%

- Decrease days sales outstanding or DSO for open invoices, enterprise-wide, more than 30%

- Reduce all past-due invoices more than 30%

Since 1993, The Lab has been able to help our clients attain benefits like these on a routine basis. And we help them do it without any tech upgrades, or rip-and-replace activity. How? As we’d noted above, most E&C firms have already invested heavily in a diversity of systems… but have yet to exploit their full potential. In other words, there’s a lot of ROI remaining to be squeezed out of these investments simply via increased operational improvement. And that starts with, you guessed it, process mapping.

How to process-map your engineering & construction firm

What is the step-by-step process for E&C firm process mapping and improvement?

This long-form explainer article from The Lab will show engineering and construction executives and their teams how to perform process mapping and improvement. We will cover:

- The opportunity of process mapping and strategic improvement

- How to map actual processes

- Which tools to use—or not

- Traps you should avoid

- How to create a benefit-rich road map for process improvement in your engineering & construction firm

The Lab has been helping E&C firms (and those from numerous other industries) with our proven, patented approach for more than three decades. If you follow this article’s guidance, you can quantifiably improve gross margin, on-time/on-budget project-completion rates, and other vital KPIs, in under 12 months.

What are the bottlenecks to identify with E&C process mapping?

How to use process mapping to reveal the ideal future state for your E&C firm

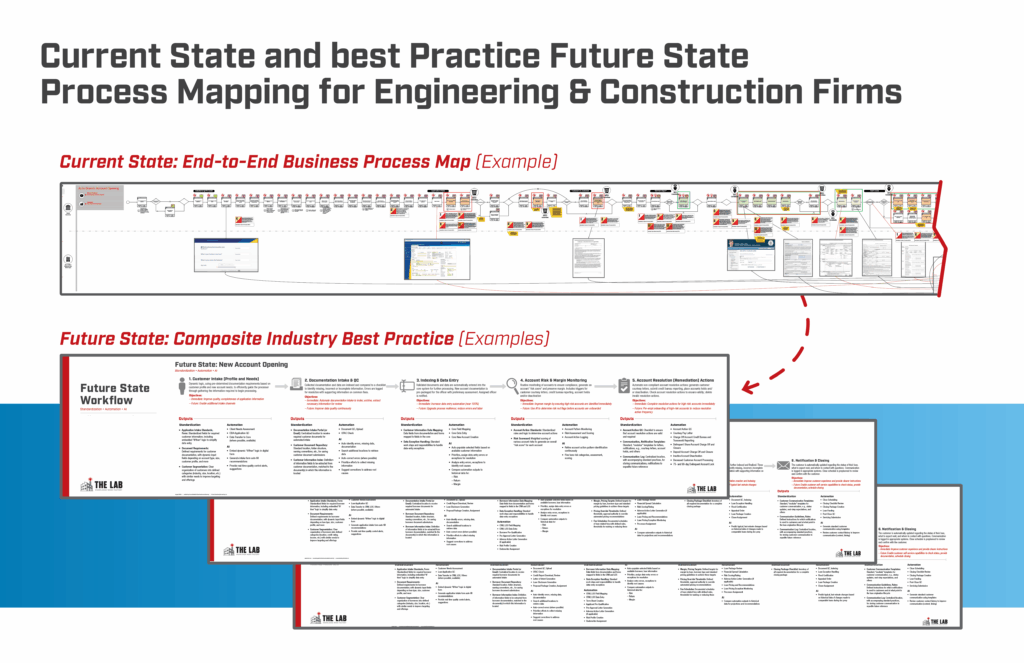

Certainly, when it comes to process mapping for engineering and construction firms, it’s typically regarded as only mapping out the firm’s current-state operations. Sure, the current state will get mapped. But it doesn’t stop there. The richest opportunities reside in the “improvement” part of “process mapping and improvement.” And that’s the future state.

Process mapping your E&C firm will help you to cut costs, improve client service, realize the most value from your existing technology investments, and drive greater improvement and enterprise value.

Whether it’s performed by an in-house team, or with the help of an external consulting partner, process mapping—we can’t stress this enough—is the critical first step for your E&C firm’s transformation. You need to process map every activity, every department, from end-to-end and wall-to-wall. This way, you’ll be able to you analyze, visualize, and spot all opportunities for future-state improvement, AI, automation, analytics, and KPI measurement in every one of your firm’s existing workflows.

You’ll also be able to reach a more valuable future state, where operational performance is maximized—thanks to your efforts to identify inefficiencies and opportunities for standardization and improvement, and introduce digital workers and AI.

How are process mapping and improvement defined in engineering and construction?

What is the definition of process mapping for E&C firms?

The Lab defines process mapping and improvement for engineering and construction firms as “a way to analyze business workflows, resulting in a visual depiction of each constituent step that’s used to perform a specific process.”

Process maps—also known as flow charts or simply diagrams—paint a clear picture of how your E&C firm’s processes are performed today. And they also reveal how those same processes can be improved in the future.

Process mapping, when done properly, breaks down even the most detailed and multiple-step tasks into discrete activities that are easy to understand… and manage. It’s the vital first step toward improving operations, efficiency, compliance, and customer service.

Understand the proper order for E&C process mapping and improvement

What are the 3 stages of process mapping for engineering & construction firms?

Stage 1: Gaining consensus

This means prioritizing strategic goals, getting buy-in across the organization, aligning the E&C firm’s business needs with the timing of the initiative, and getting the E&C firm ready for the process improvement that will result. This stage can be short or long. It requires the most effort, however, as it’s the most “political.”

Stage 2: Drafting the maps

Drawing the actual process process maps and documenting the identified improvements is the quickest—and dare we say “most fun”?— stage.

Stage 3: Implementing transformation

Implementing transformation of the improvements which have been prioritized and road-mapped by the E&C organization. This is longer-term. It’s a continuous-improvement stage. And it makes good on the benefits identified in the original business case.

Now let’s look at these stages in more detail

E&C Process Mapping Stage 1: Gaining consensus

Timeframe: 3 – 18 mos.

- Choose the project sponsor from the C-Suite

- Identify a problem needing solving—across the entire E&C enterprise or at a given business unit

- Define the strategic outcomes desired from the process-mapping initiative

- Identify a cross-functional, “wall to wall” scope that’s rich in benefits

- Gain organizational and departmental buy-in/consensus

E&C Process Mapping Stage 2: Drafting the maps

Timeframe: 6 – 12 wks.

- Collect all organizational operating procedures across the organization; you needn’t worry in case they’re outdated

- Identify all business systems (core and ancillary) being used. List the different types of data available for analysis

- Meet with your internal subject matter experts or SMEs

- Draw workflow diagrams in detail. Document every single activity within a given process at the 1- to 5-minute level of detail

- Conduct a Map Fair to crowdsource extra improvements which didn’t appear in the initial pass

- Identify, then catalog, then build a taxonomy of process improvements which can be implemented

- Create the business case and future-state transformation work plan for your engineering and construction firm

E&C Process Mapping Stage 3: Implementing transformation

Timeframe: 3 – 12 mos.

- Build your E&C firm’s implementation & support teams; populate them accordingly

- Standardize all internal business processes

- Reduce and/or eliminate any unnecessary or redundant processing

- Improve quality data where it’s poor; fix it where it’s created

- Onboard digital workers (agentic AI, robotic process automation or RPA) and advanced analytics/data intelligence/dashboards

- Support your newfound capabilities via KPIs which manage your E&C firm’s progress toward its stated goals

Creating process-mapping capability in-house at engineering & construction firms

How do you select the internal or external teams to perform process mapping at your E&C firm?

For E&C firms that have already invested in internal improvement, their existing business-process-mapping teams are usually formed from their internal-improvement teams across the different business organizations.

The most common job title for a process-mapping team member is usually “Business Analyst” or “Process Engineer.” As your E&C firm’s needs for data-driven process-improvement expand, be sure to seek out data scientists who have process experience. Then back them into the customary business-analyst role. Note, however, that process-mapping teams rarely reside within IT.

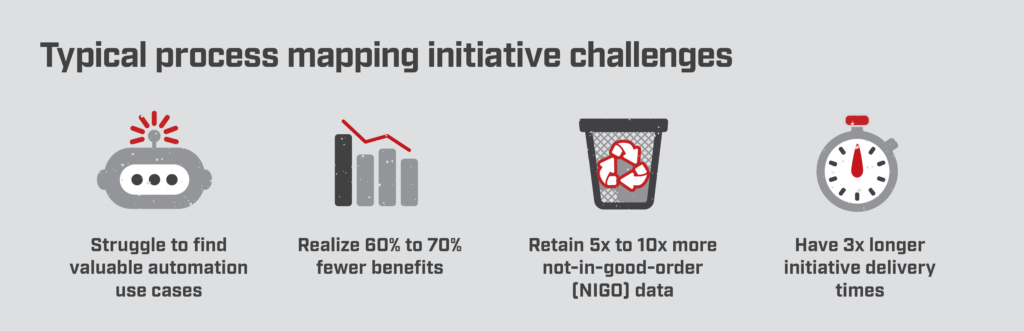

It’s uncommon for E&C firms to possess a mature internal team which can perform organization-wide end-to-end business process mapping. The state of smaller/mid-sized firms mirrors that of their larger peers, with 70 percent lacking mature business-process-mapping capabilities that can manage enterprise-wide mapping initiatives.

Looking outside, the largest engineering and construction firms, spanning North America and globally, often use external consulting firms to help map their existing processes.

When does this happen? These E&C process mapping activities often occur when the firms implement process improvements, merge disparate organizations, or onboard new systems.

What kind of firm should E&C businesses hire for process mapping and improvement?

Process-mapping services, such as those offered by The Lab, are basically turnkey offerings for engineering and construction firms:

- The Lab runs the projects.

- The Lab develops the maps.

- The Lab provides the teaching methods which we’ve honed across hundreds of other organizations and client engagements.

Indeed, The Lab has transformed our more than three decades’ worth of process mapping experience into standardized tools and templates; these are used to accelerate the “process-mapping process” for our E&C clients.

What are the best software platforms for E&C process mapping?

How to choose the best software for process mapping in engineering and construction

Here’s a rundown of today’s most popular tools for creating process maps for E&C firms:

Tool 1: Physical or electronic whiteboards

- These are ideal for quick summaries

- Good for group meetings where summary flows are sketched out

Tool 2: Paper rolls (white or brown)

- Typically hung on a wall

- Handwritten or drawn

- Easy to pepper with diagrams or Post-it notes

- Often used by traditional consultants

Tool 3: Microsoft Visio

- Ubiquitous and easy to install; just use Office 365 from MS

- It’s the most popular process-mapping software for the last ten years

Tool 4: Signavio

- It’s a cloud-based application

- It can serve as an alternative to Microsoft Visio

Tool 5: IBM Blueworks

- This is proprietary process-mapping software offered by IBM

- It’s seen a reduced presence and market share in the past few years

Which external consultancy offers 30-plus years of process-mapping experience?

How does The Lab differ for E&C process mapping and improvement services?

Our unique templatized approach to process mapping and improvement surpasses the limitations of traditional methods employed by engineering and construction firms:

- Better outcomes. The Lab will benchmark your E&C operations against engineering and construction industry best practices. This lets us ID competitive gaps—and helps us design an improved future state for your firm.

- Many more improvements. When you’re able to understand all of your E&C firm’s end-to-end processes at the activity level, you can identify avoidable effort and redundant rework. You can see more opportunities for introducing agentic AI, automation/digital workers, advanced analytics and data intelligence, control points, and more.

- More benefits. When you can measure the exact capacity requirements of each of your E&C firm’s business processes or departments, you can create a benefits case which will guide improvement implementation.

- Faster analysis. The Lab’s process analysis is designed to be efficient. We’ll need just 1 hour, each week, from your staff, over a six- to eight-week span. So you—and they—can focus on core activities. Let The Lab develop and validate the process mapping and analysis.

How does The Lab determine project-map scoping for engineering and construction firms?

Best practice scoping for E&C firms process mapping and improvement

As we’d noted—and as you know—there’s a huge range of engineering and construction firms out there. They vary by engineering discipline, by project role or service, and by project sector, too. Considering that they span everything from residential construction to public-works infrastructure projects, you wouldn’t think that they’re more alike than different. But it’s the case. And it holds true even across different sizes of E&C firms.

No matter what they’re engineering and/or or constructing, the essential milestones and gated operational stages will be mostly similar—by about 80%—between, say, E&C Firm 1 and E&C Firm 2. The biggest differences between them, typically, will be the relative level of un-standardization within each firm’s core systems. That’s because they each will have been configured according to the original implementers.

No matter. The similarities between E&C Firm 1 and E&C Firm 2—and your firm—make scoping very similar, and fast, for The Lab.

When you’re scoping a process-mapping initiative in engineering and construction, be sure to follow these best practices:

- Look to maximize your ROI via a scope that’s rich in benefits

- Perform your mapping across all of your E&C firm’s different departments and functions

- Sidestep silos within the organization

- Be sure to document every phase of the the sales process, the client’s journey, all back-office operations, and each regulatory stage gate.

- Map out engineering and construction business processes from wall to wall and end to end:

- Include project management from planning, job costing, and forecasting all the way through field operations, setup, and close-out

- Document billing and collections from T&E entry through the invoice creation, to collections, payment processing, and all reporting activities

- Insist on executive-level sponsorship, so you can avoid the possibility of internal organizations finding excuses to duck out

Which systems should you include in E&C process mapping?

Engineering and construction firms often wonder, when embarking upon a process-mapping project: “Which systems should we include in our process mapping?”

The answer: All of them. These include your specialized platforms , including:

- Design systems, such as AutoCAD and SolidWorks

- Building information modeling or BIM platforms like ArchiCAD and Revit

- Simulation software for computational fluid dynamics (CFD) and stress, such as COMSOL and ANSYS

- Drone and robotics tracking software

- Telematics and IoT platforms for things like tracking equipment usage

- 3D printing software used in prototyping

These also include all of your ancillary systems like your CRM, HRIS, and even MS Teams. And don’t overlook any data warehouses you use.

Just as you shouldn’t exclude any departments in your E&C process mapping, you shouldn’t exclude any of the numerous systems your firm uses. When you include all of the systems you use, you get more “bang for the buck” from this wall-to-wall approach.

How does The Lab process-map E&C firms in six to eight weeks?

Reasons why The Lab can process map E&C firms from end-to-end in just 6 – 8 weeks

With more than three decades’ worth of process-mapping experience under our belt, The Lab has honed a standardized approach to process mapping which we use for engineering and construction firms like yours. This applies to our standardized current-state process mapping as well as our templates for the future state, using our templates and best practices from our Knowledge Base.

Taken together—along with our passionately process-focused team—The Lab can perform E2E process mapping of engineering and construction firms in just six to eight weeks. Here’s how we do it:

- We map business processes from start to completion at the one- to five-minute level of activity detail.

- We layer essential operations and improvement detail atop each map.

- These layers include customer touch-points, system usage, job roles, unproductive effort, standardization opportunities, automation/digital worker use cases, and more.

Despite all the work we do, we don’t throw any wrenches into the gears of your E&C operation. At each step, we’ll only need about one to two hours of time from your subject matter experts, per week. It’s our intent to minimize the drag on your team during the process-mapping engagement.

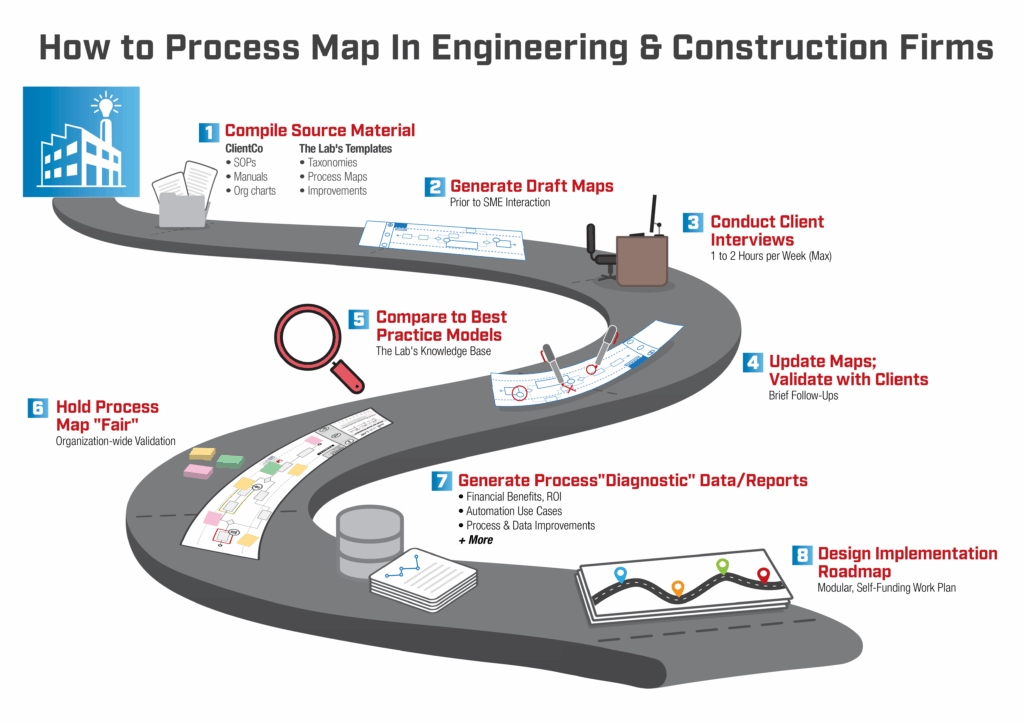

What are the 8 steps for process mapping an engineering or construction business?

The Lab employs a best-practice method when we engage with engineering and construction firms to process-map their businesses. We follow a brisk operational tempo, too. Here are the eight steps of our process-mapping process:

E&C Process Mapping Step 1:

Gather all existing source materials

Your E&C firm has amassed a lot of materials over the years: Process information. Policies. Procedures. Manuals. At The Lab, we’ll want all of it, right from the get-go.

Many engineering and construction firms, when faced with this request, fret over the condition of these materials. Don’t fret. We don’t care what kind of condition they’re in, nor how old, how incomplete, whatever. The point is that we want to review every last bit of your engineering and construction firm’s process-mapping attempts at documentation. We want to conduct the most thorough research possible before we engage with your people.

We want everything. In any condition:

- SOPs

- Manuals

- Org charts

- Department structures

- Operational reporting

We don’t care if your business’ KPIs are buried in numbing Excels or interminable PowerPoints. Just hand ‘em over.

And that’s just the documentation. We’ll also want data, in the form of extracts from your different systems: ERP, CRM, CAD, BIM, FEA, CFD, HRIS, pick your acronym. Now when we mention things like “HRIS” or “CRM,” you needn’t worry. We only want redacted information, free of any personally-identifiable information or PII, and with no customer-sensitive information or CSI.

It’s not simply that we’re being polite. Fact is, we don’t need that information to find KPI-driven trends such as:

- Payment-processing rework

- Variance in project budgeting

- Open invoices days sales outstanding (DSO)

- The % of work orders that have been resolved within SLA

- Volume of not-in-good-order (what we call “NIGO”) information moving through your E&C firm’s billing or collection process

What we do with all of this information next, speaks to The Lab’s core competency as an implementation firm:

- We compare the data to the process maps in our Knowledge Base

- We use this information to create a capacity model of your E&C business’ current state

- Vitally, we use this information to list out the specific improvements for the implementation’s business case

The Lab’s Knowledge Base, which we’d mentioned above, plays a key role here; we’ll compare your data to that which we’ve amassed and catalogued over 30-plus years, analyzed from previous processes and best-practice peers. As we’d noted earlier, Engineering & Construction Firm “A” isn’t radically different from Engineering & Construction Firm “B,” regardless of your discipline or specialized trade. The similarities allow us to fill in the gaps.

Our Knowledge Base is packed with IP. It features tools and templates for things like:

- Process maps

- Taxonomies

- Improvements including

- Use-cases for E&C automation, robotics, digital workers, and agentic AI

- KPIs or Key Performance Indicators

- E&C standardization opportunities

- Re-organizations

- Benchmarks

- Proven best practices

E&C Process Mapping Step 2:

Draft first-version engineering & construction process maps

After The Lab has received and processed all of the E&C operational data we’d requested in Step 1, we draft the initial version of your engineering and construction services firm’s process maps.

Importantly, we won’t even have engaged with any of your subject matter experts or SMEs yet. It’s because we want to be as respectful of their time as we possibly can.

The Version 1 process maps that we draft are created in Microsoft Visio. We purposely use this popular program so you can freely update them after the engagement is complete; there’s no need to purchase or learn new software.

(Besides, we realize that no E&C business that wants its processes mapped also wants consultants hanging around their offices forever!)

E&C Process Mapping Step 3:

SME (subject matter expert) interviews

Now that the Version 1 process maps have been drafted, The Lab asks for some of your SMEs’ precious time. These are the people who are actually performing the work depicted in the maps.

Via Teams or Zoom, we’ll share the Version 1 maps with the SMEs. Using questions which we draft in advance, we’ll ask them to verify what we’ve mapped thus far—and, importantly, to clarify any gaps that we believe may exist in a given process.

We use these interview notes to build further details into the maps. We only need about one to two hours, per week, with your SMEs, as we want to be as respectful of their precious time as possible.

E&C Process Mapping Step 4:

Iterate and update the E&C process maps

At The Lab, we’ve discovered, over the course of three-plus decades, that no E&C SME can recall every single step of a given process at a single sitting.

That’s another reason our time engagements with them are so frugal. We’ll work with your team over the course of the next four weeks, multiple times, to review the continually-updated E&C process maps with them in brief “bursts.”

Spreading out these interactions and iterations (think: “lather/rinse/repeat”) delivers the optimum level of detail for the current-state process maps.

E&C Process Mapping Step 5:

Best-practice comparison

The current state is only the beginning. And The Lab’s Knowledge Base helps us take things to the next level. Because we’ll compare the process maps from your engineering and construction business to best-practice models. We’ll review peer industry comparatives. This, then, becomes the basis for building out the most value-laden future state that can be implemented.

The Lab’s Knowledge Base includes best-practice models for:

- Improvements

- KPIs

- Job descriptions

- Digital workforce use-cases for E&C automation and AI

- Benchmarks

- Data and process standardization opportunities

- Opportunities for more effective re-organization

E&C Process Mapping Step 6:

Map Fair crowd-sourcing feedback

After drawing up the maps, building out their detail with the help of the SMEs, and validating the findings against the best practices in our Knowledge Base, it’s time for The Lab to share the process maps with your entire engineering and construction organization.

These are what are known as Map Fairs. We conduct them live, typically in large common areas of your organization’s headquarters. This way, your team can review and contribute, at their leisure, over the course of two days.

Each Map Fair serves to socialize the findings from the previous process-mapping effort. It prepares your E&C organization for future process change. It generates buy-in from your team, since everybody can contribute.

During the two-day Map Fair, your E&C team members are free—indeed, encouraged—to mark up the map with color-coded Post-It notes:

- Green Post-It’s: “I agree with this.”

- Yellow Post-It’s: “Additional steps or improvements should be added here” or “There’s some missing information.”

- Red Post-It’s: “I disagree with this.”

By adding to the process map—even anonymously, if they prefer—your team members validate the fact base and process map which The Lab has created with, and for, your E&C business.

Once the Map Fair has ended, The Lab analyzes every single Post-It note. We reconcile them into an updated version of the workflows. At this point, the as-is process maps for your E&C firm are considered to be finalized.

E&C Process Mapping Step 7:

Build E&C capacity model and reports

The two-day Map Fair does more than validate the process maps for your engineering and/or construction business. It opens the road to literally hundreds of improvements, organization-wide. Map Fairs typically reveal:

- Anywhere from 100 to 200 automation and AI use cases

- Anywhere from 150 to 250 standardization opportunities

- From 50 to 100 analytics use cases

All of this opportunity gets aggregated, by The Lab, into a single, centralized database, replete with an easily navigable MS Power BI dashboard. This is used to help you prioritize and plan the order of the improvement opportunities which have been identified.

This prioritization is quantified in terms of:

- Financial benefits

- Time savings

- Measurable improvements in customer experience

- Identified platform or technology under-utilization

- More

Using this compilation of discrete quantified improvements, The Lab then generates an all-inclusive organizational capacity model for your E&C business. This acts as a baseline for determining the value and business case for implementation, work plans, and subsequent modules.

Outputs feature:

- Process & data improvements

- Financial benefits & ROI

- Digital workforce/automation/AI use-cases

- Plus many others

E&C Process Mapping Step 8:

Draft improvements implementation roadmap

Now that you have all of these newfound improvements in-hand, you should rush to implement them all, all at once. Right?

Wrong. Nothing against your engineering or construction services firm, but regardless of your operational prowess, you shouldn’t attempt to do them all at once. You’ll only fall short.

At The Lab, we’ve learned that’s it’s much more efficient to build incremental modules for implementation of identified improvements. These should align with your strategic plan and be carved into short-term, mid-term, and longer-term segments.

The Lab can and will help you to implement the identified improvements… at first. As the continuous-improvement effort, well, continues, you’ll be able to assume more of them yourself. This organic hand-off typically produces far more long-term benefits than a single big-bang attempt.

E&C Process Mapping Step 8 outputs include a self-funding, modular work plan. This plan is designed, jointly, by The Lab and your executive steering committee; it’s crafted to meet your E&C firm’s strategic objectives. Its schedule is dictated by business calendar quarters, and includes a combination of process improvements, digital workforce onboarding/AI, and KPI advanced analytics.

There is an exception to the incremental-approach rule we just described. Sometimes, albeit rarely, “big bang” is the way to go. The Lab has helped some of the world’s biggest re-orgs, when “all at once” was warranted.

How can E&C firms increase their operational efficiency and process resilience?

List of the Top 5 Benefits for Engineering & Construction Process Mapping

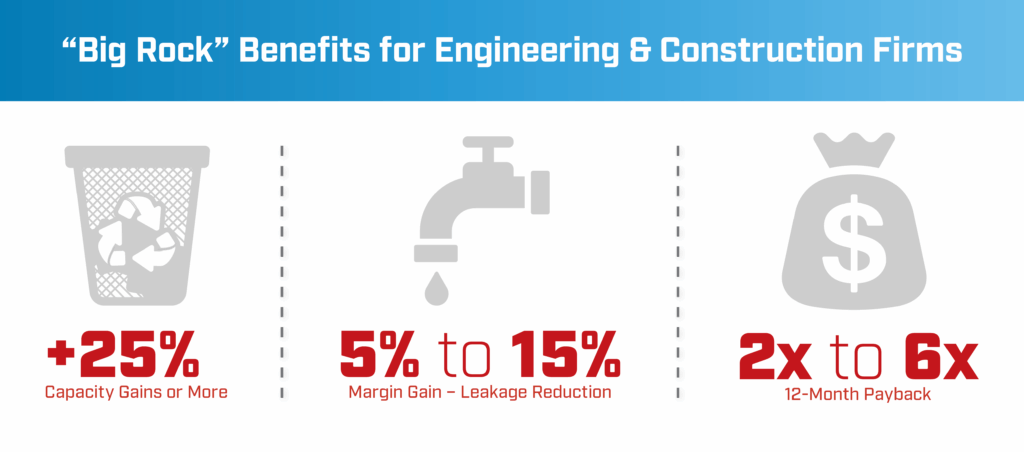

Discover how your firm can achieve 25%+ capacity gains, 5–15% margin improvement, and up to 6x ROI in 12 months through strategic operational enhancements.

Let The Lab help your business transform rapidly

How to start process mapping for engineering & construction firms

For more than 30 years, The Lab has helped E&C business’ C-suite execs, technology and business-unit leads, and their own internal improvement teams to map out all of their companies’ business processes and client journeys. This has helped to increase client satisfaction and retention, boost efficiency, streamline operations, and realize substantial cost savings. We identify and implement automation and AI opportunities as well as advanced analytics to improve your firm’s process resiliency, while helping to reduce employee turnover. We’ve built our reputation via comprehensive solutions that deliver quantifiable benefits and ROI, driving success.

Are you ready to transform your engineering and construction firm? Book your screen-sharing demo with The Lab: Simply call (201) 526-1200 or email info@thelabconsulting.com today.