Standardization Helped Meet Customer Expectations & Ease Competitive Pressure

Changes in the healthcare industry demanded improved capabilities from pharmaceuticals companies. Customers wanted flexible ordering options, shorter cycle times, new packaging, increased service support—and lower prices. The company’s new ERP upgrades promised to enable this new flexibility, increase productivity, and deliver sustainable cost reduction. But it also delivered mediocre gains. Rapid turnover was only exacerbating operational issues.

Various initiatives including workflow implementation, lean Kaizen events, and robotic process automation (RPA) technology made little headway on improvement to meeting the demanding new customer expectations. Internal automation teams and citizen developers were starved for automation opportunities and use-cases. One team leader learned about The Lab’s process standardization and discovery templates and arranged a meeting.

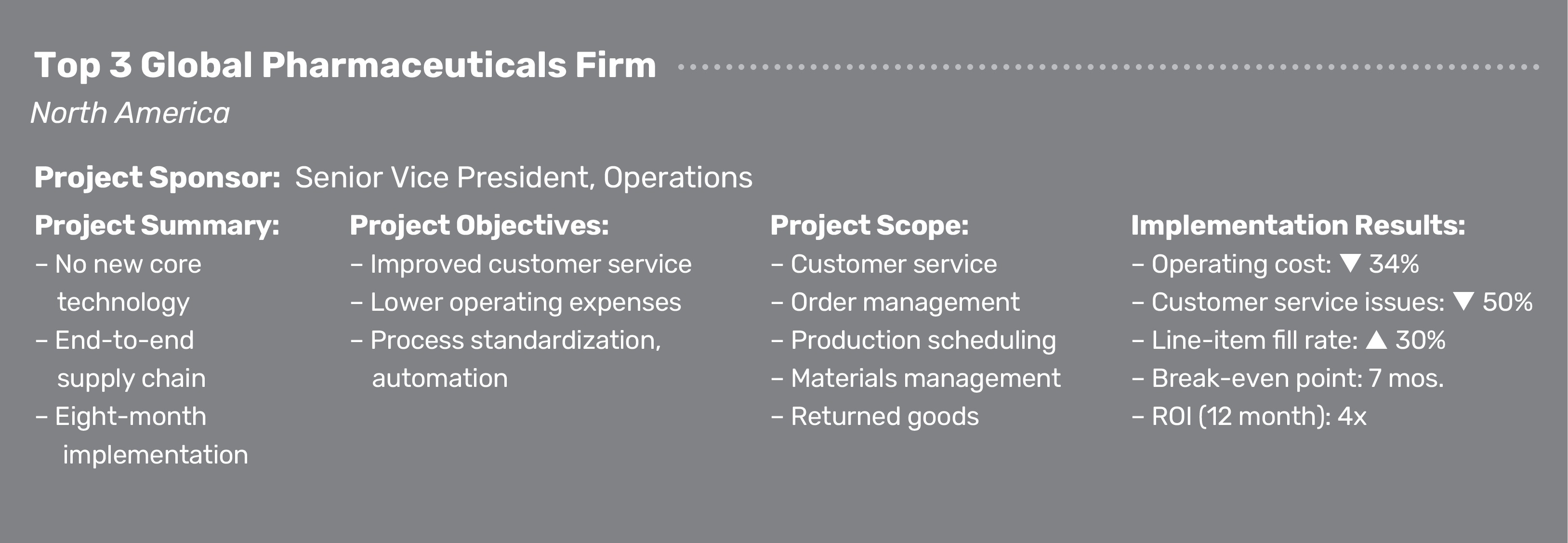

Client Description, Project Scope, Objectives

The company is the North American subsidiary of a top 3 global pharmaceuticals industry firm. Nearly 5,000 employees oversee research, development, manufacturing, sales, and distribution. The improvement effort focused on supply-chain operations, including sourcing, order management, production, distribution, and customer service—involving 3,000 employees.

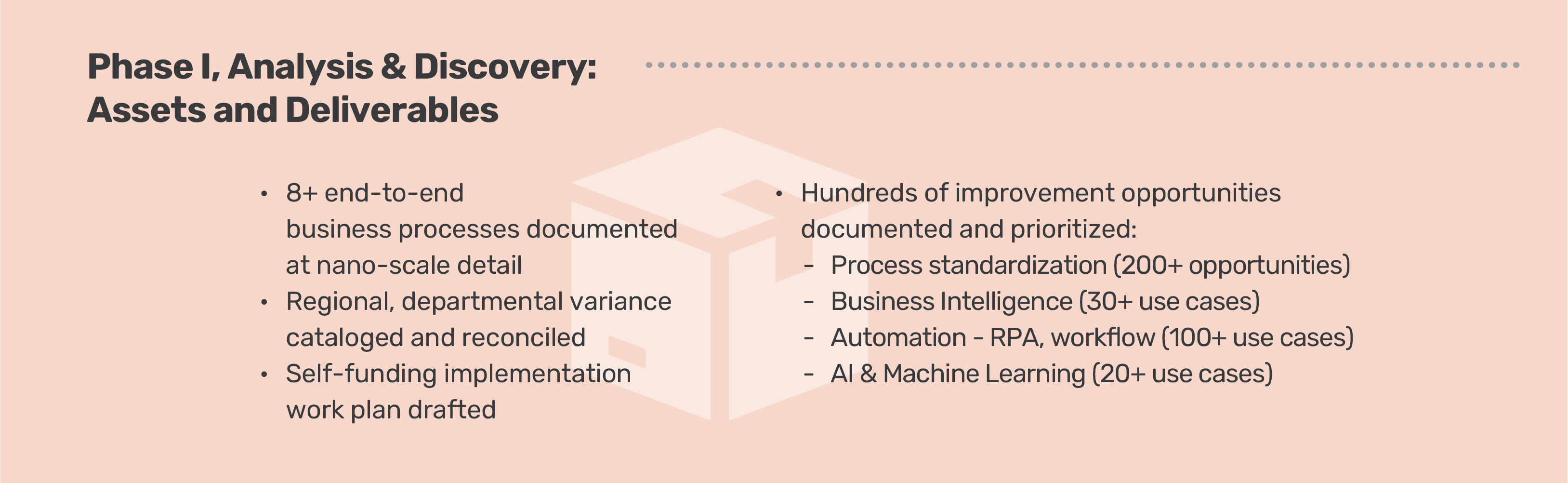

Phase I, Analysis and Discovery

Within eight weeks, The Lab’s standardized process map and discovery templates enabled documentation of all major end-to-end (E2E) business processes for 3,000 supply-chain employees. More than 85 percent of work activities (approximately two minutes each, or less) were documented while only requiring one hour per week of any subject matter expert’s (SME’s) time. The Lab’s Standardization Platform and advanced analytics models mined, compiled, and generated insights for the maps from internal client data: event logs, org charts, volumes, cost-center data, and much more. The Lab’s external data provided benchmark comparisons, best-practice comparisons, and automation use-case comparisons.

Coordinating and reconciling the E2E maps with both internal and external data resulted in maps that could easily be directly reviewed, refined, and validated by thousands of the supply employees—even with the company’s overseas divisions in Europe and Asia.

Phase II, Implementation

The eight-month Phase II implementation effort was able to increase productivity, compress cycle times, improve customer service, and deliver cost reduction. Line-item order fill-rates improved by 30 percent. Avoidable contacts to the customer service center were cut by half.

The Lab implemented selected standardization opportunities and automations that had been discovered, alongside the client’s internal resources. The senior executive sponsor of the initiative adopted a decentralized approach.

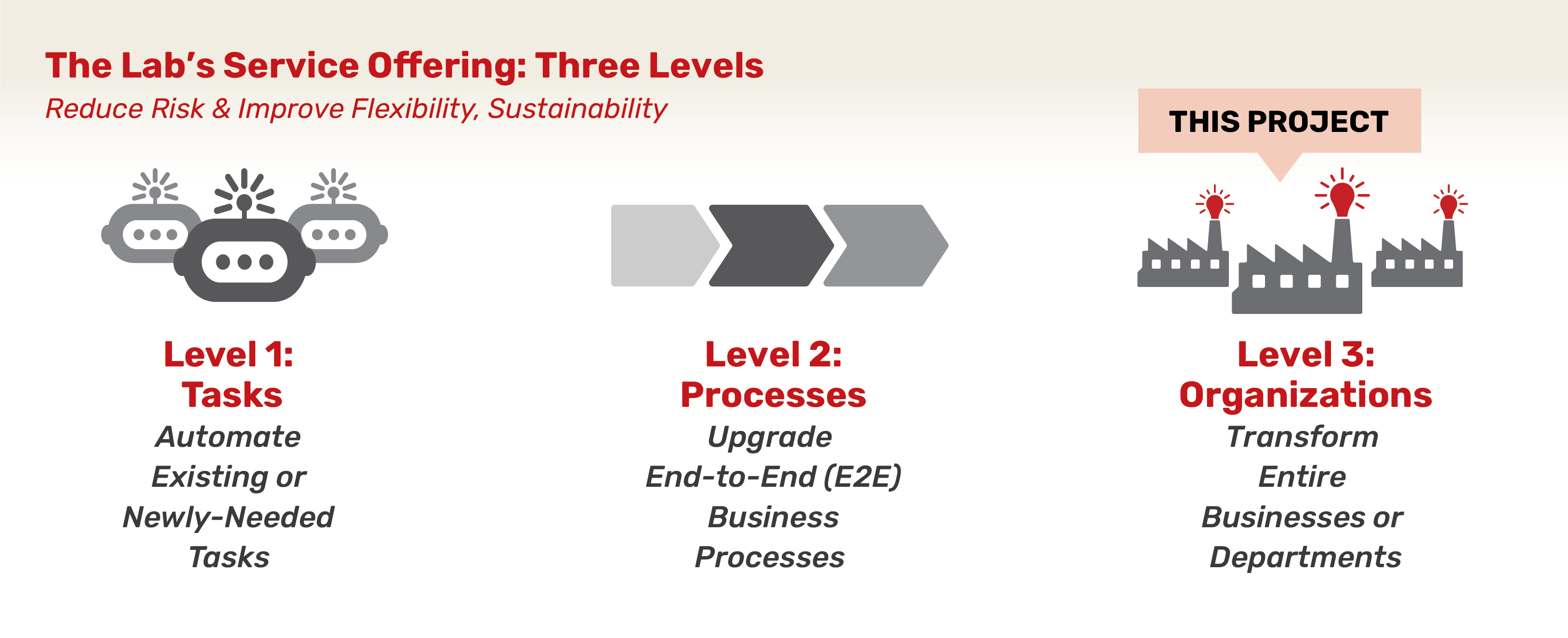

Improvement goals were established by area and/or by E2E business process, and the organizations involved could perform the work with any mix of resources they chose: internal resources, The Lab’s resources, or others. The Lab maintains a three-tiered service-offering structure (plus post-implementation support) to make implementation flexible and sustainable for clients:

Post-Implementation Support, Sustainability & Automation

The Lab provided hassle-free post-implementation hourly sustainability support for this client to maintain automations, process standardization, and operational data analytics models implemented during the Phase II engagement. If the client’s team was not up-skilled enough to perform any needed automation updates, they leaned on The Lab for Tier 3-level support. If analytics dashboards required additional views or data connected, The Lab’s team was a simple phone call away.

Improvement Examples, Service and Distribution Standardization

The Lab implemented over 140 process-standardization opportunities to reduce variance and 30-plus automation candidates to increase service, productivity, and efficiency. Examples:

The Lab Makes it Easy

Organization-friendly engagement design

At The Lab, we’ve spent three decades refining every aspect of our transformation engagement model. We’ve made it easy for clients—from the C-Suite to the front line—to understand and manage the initiative:

• Minimal use of client time: One to two hours each week, maximum.

• Measurable benefits: Typical 12-month ROI is 3x to 5x.

• Pre-built templates and tools: Process maps, data models, bots, and more.

• U.S.-based, remote delivery: Nothing is ever outsourced or offshored.

Designed to reduce risk, increase success

Since 1993, The Lab has led the industry in eliminating risk for our clients. Whether your engagement involves a handful of bots or wall-to-wall transformation, we make it easy to do business with us:

• Fixed pricing and clearly defined scope

• Pre-project feasibility/value assessments at nominal cost

• Early-out checkpoints and options

• Money-back guarantees

Book your free demo

The best way to learn about The Lab’s patented Knowledge Work Standardization® approach is to book your free, no-obligation 30-minute screen-sharing demo. And you’ll get all your questions answered by our friendly experts. Simply call (201) 526-1200 or email info@thelabconsulting.com to book your demo today!