Situation

The new COO of this retailer’s Global Shared Services (GSS) Center had spent nearly her entire career in similar global-scale shared-services centers. Five years prior, she was recruited by a colleague who had earlier joined the retailer from a large defense contractor’s shared-services organization where they had both worked. Her career move paid off with the COO title.

The position was moderately challenging but delivered no big surprises—until now.

After completion of the largest IT upgrade investment in the retailer’s history, senior management decided to relocate selected regional store-support operations into the nearest GSS.

The selected operations had little in common; they were holdovers from earlier days. Many of the activities were duplicative of those already performed in the GSS:

- Vendor onboarding

- Invoice processing

- Credit

- And more

Others were highly specific to products or industry segments:

- Telecom services

- Healthcare services

- Others

But now, in order to combine this consolidation into the firm-wide effort to become leaner, the transfer was directed to be made without any increase to existing GSS employee headcount.

By the COO’s reckoning, this would require roughly a 20-percent productivity gain. The activities were scheduled to be transferred quickly—over a nine-month period.

The COO kept a personal box of materials received over the years that she found especially interesting and valuable. She brought this box with her when she joined the retailer. Now, she opened it, dug out the “Standardization” folder from The Lab, and made contact.

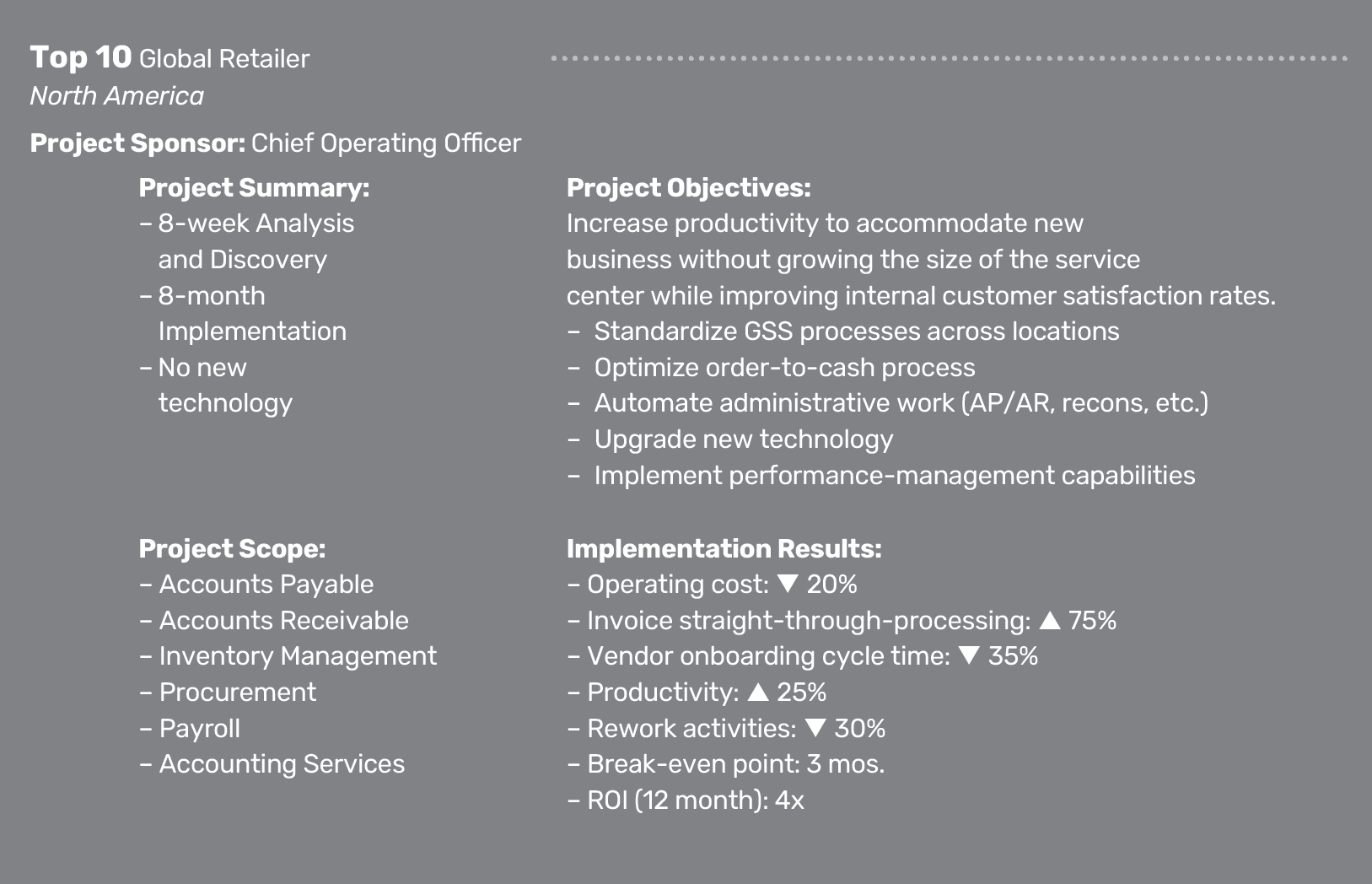

Client Description, Project Scope, Objectives

The client operates one of the largest retail chain networks in the world, with thousands of stores supported by the North American Global Shared Services (GSS) Center—one of several similar centers worldwide. These centers handled everything “downstream” from purchasing and transportation:

- Supplier onboarding

- Relevant master data

– Primarily vendor master

– Product master

– Order master - Accounts payable

- Accounts receivable

- Payroll

- Hiring

- Help-desk services

The scope of the GSS Initiative included almost 3,000 employees in three locations: two adjacent, and one remote, which was scheduled to be shuttered after the consolidation.

North America was selected as the pilot location, with successful strategies planned for rapid rollout to other shared-services centers worldwide, starting with Europe.

Beyond the primary objective of efficient consolidation, the second objective was “re-use” of best practices. The business-process maps, standardization improvement inventories, automation candidates, and regional best practices were documented for these initial GSS locations and then “gap tested” among the worldwide shared-services network.

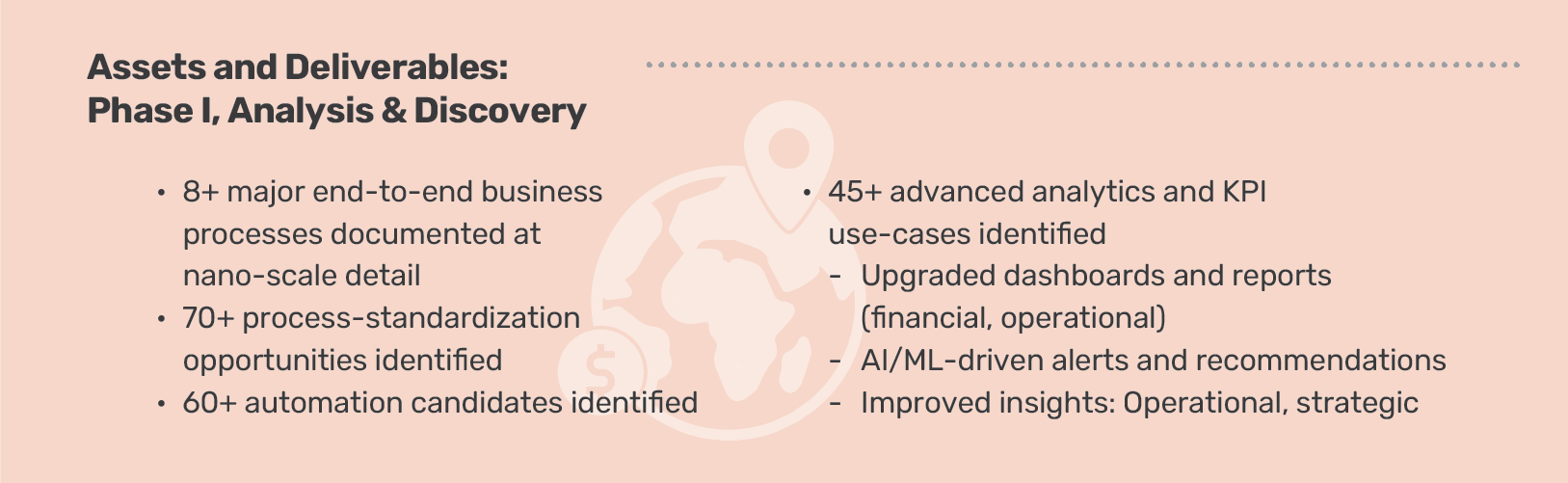

Overview: Phase I, Analysis and Discovery

The GSS Initiative began with an eight-week Phase I analysis covering the major end-to-end business processes, including:

The Lab deployed our proprietary shared-services standardization templates, including:

• Industry-standard KPIs

• Related data taxonomies

• Business process maps

• Operations benchmarks

• Best practices

• Automation “use cases”

• And more

These enable rapid, remote documentation and analysis of more than 85 percent of employee work activities (approximately two minutes each), while only requiring one hour per week of any subject matter expert’s (SME’s) time.

During the Phase I analytical effort The Lab identified over 175 improvements in the North American GSS operations.

Just over 40 percent of these represented non technology standardization improvements that boosted operational effectiveness, reduced avoidable rework, and/or enabled automation.

While the remaining improvements were technology-dependent, no new systems were required.

- Roughly half could be automated using the existing technology after the work was standardized.

- The remainder were automated using robotic process automation (RPA), and small, low-code applications (e.g., automated forms, APIs, etc.).

- Many automations could be further augmented with artificial intelligence (AI) for simple decision-making and proactive, real-time notifications.

All of these improvements, moreover, could be implemented in eight months or less.

Better yet, benefits from non-technology standardization “quick wins” began to accrue within six weeks of the start of implementation. These quick wins built momentum and helped to fund further improvements throughout global operations.

Findings: Phase I, Analysis and Discovery

Although the content of each finding was specific to each organizational area and the various related transactions, all could be grouped into four categories in roughly similar proportions:

1. Measurement. Minimal reporting existed for GSS operations at any location. Although store operations were closely measured, internally benchmarked, and reported for each shift, GSS was traditionally viewed as “accounting” and considered “unmeasurable.” This perception squandered valuable productivity due to high variation in performance for identical work activities.

2. Standardization. Given the perceptions that led to the lack of performance measurement, it was unsurprising that opportunities to standardize were largely overlooked. Most work routines and instructions were undocumented, existing as tribal knowledge and transferred verbally. As a result, similar processes at the three GSS locations were being performed in three separate, non-standard ways.

3. Existing system adjustments. Employees and IT staff paid scant attention to the business implications—advantages and disadvantages alike—of the recently-deployed suite of ERP and related technologies.

Example: The A/P intake module had been configured to process only invoices with purely numeric identifiers. If an invoice’s numbering scheme included alphabetical characters and numbers, the system returned the invoices to suppliers without explanation—generating more than $4 million in capacity lost to rework and inquiry processing each year. A system adjustment to correct this issue was completed within days.

4. New digital automations. The client’s internal robotic process automation (RPA) team initially struggled to identify use-cases, stalling at about a dozen operational bots. Over time, they focused on smaller-scope automations and increased the total number of operational bots by more than tenfold. However, each bot delivered negligible value—and nearly 40 percent of bots performed rework corrections that were avoidable with better instructions, standardization, and minor modifications of existing systems.

Overview: Standardization Implementation

The COO knew that GSS needed a “transformation” but that they were reluctant to use that word. They wanted change without disruption. From the analysis, they knew they had sufficient, up-to-date technology infrastructure (cloud-based ERP and CRM systems).

They worked with The Lab to craft a “light-touch, minimally-invasive” approach to standardization implementation. It began with a network of selected “Super KPIs.” These were performance indicators that subtly delivered three critical transformational capabilities at non-disruptive “nano-scale”:

1. Prediction. Which customers were most likely to pay outstanding balances? Which SKUs should be removed from inventory due to low profitability or obsolescence? Data analysis helped select KPIs that answered many of these critical questions.

2. Preemption. Who should be notified to avoid the consequences of errors and customer dissatisfaction? Who should be notified of low-inventory items before stockouts occur? KPIs linked with RPA bots, and sometimes basic artificial intelligence (AI), can easily deliver preemptive capabilities.

3. Prescription. What root causes can be addressed to institutionalize the learnings from above? Selected KPIs can point the way and store many of the insights to help improve forms, business processes, and organizational responses.

This is how the executive leadership team (ELT) was able to gradually transform GSS without disruption. Leveraging the “Super KPIs” noted above, only the “critical few” data elements, dashboards, and work activities were changed at each step, supported by fact-based data analysis. Performance targets and thresholds were established for each KPI. Notifications could be sent confidentially to employees and managers to help them predict and preempt, avoiding uncomfortable “coaching” sessions.

Global Shared Services Improvement Examples: Phase II, Implementation

The Lab implemented more than 175 standardization improvements that reduced rework, increased scale, and enabled automation across GSS. Examples:

Post-Implementation Support, Sustainability & Automation

The Lab provided hassle-free post-implementation hourly sustainability support for this client to maintain automations, process standardization, and operational data analytics models implemented during the Phase II engagement.

If the client’s team was not up-skilled enough to perform any needed automation updates, they leaned on The Lab for Tier 3-level support. If analytics dashboards required additional views or data connected, The Lab’s team was a simple phone call away.

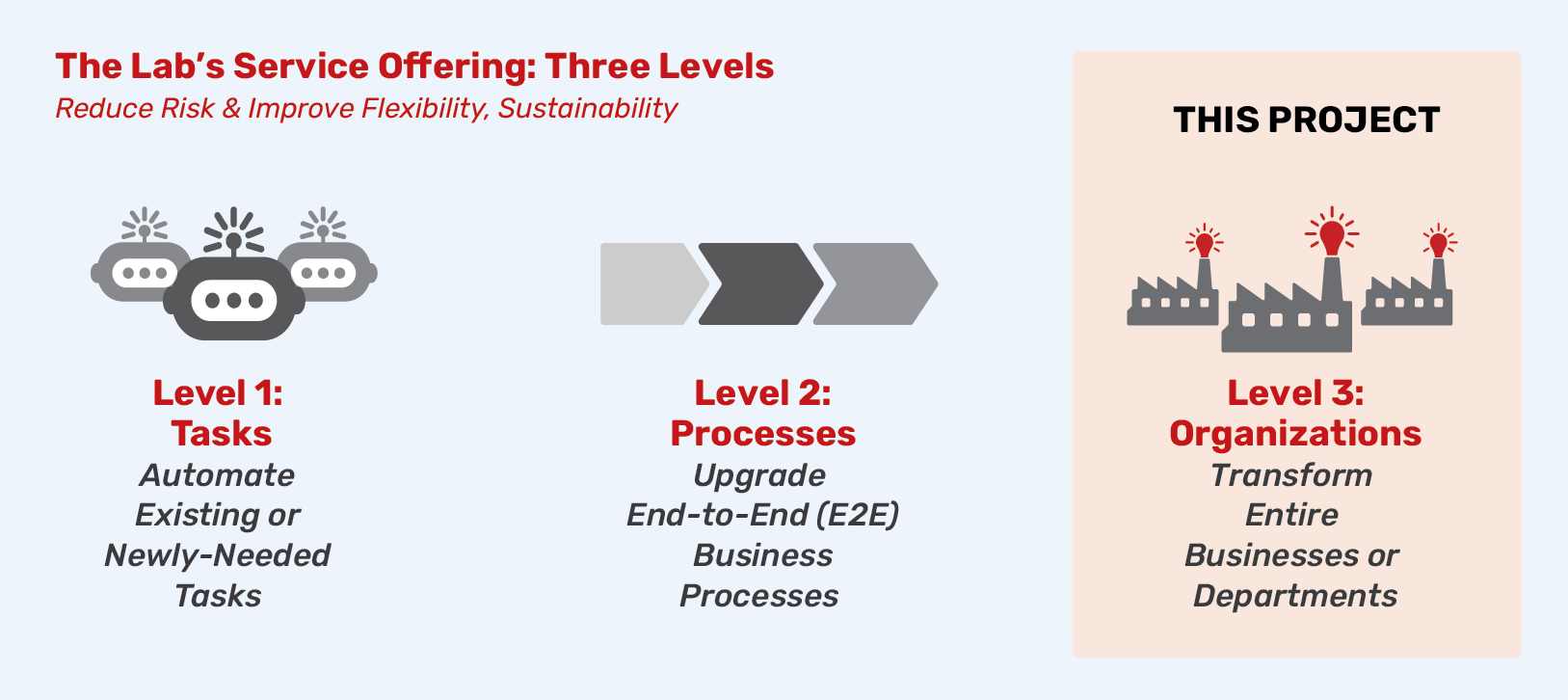

The Lab Makes it Easy

Organization-friendly engagement design

At The Lab, we’ve spent three decades refining every aspect of our transformation engagement model. We’ve made it easy for clients—from the C-Suite to the front line—to understand and manage the initiative:

• Minimal use of client time: One to two hours each week, maximum.

• Measurable benefits: Typical 12-month ROI is 3x to 5x.

• Pre-built templates and tools: Process maps, data models, bots, and more.

• U.S.-based, remote delivery: Nothing is ever outsourced or offshored.

Designed to reduce risk, increase success

Since 1993, The Lab has led the industry in eliminating risk for our clients. Whether your engagement involves a handful of bots or wall-to-wall transformation, we make it easy to do business with us:

• Fixed pricing and clearly defined scope

• Pre-project feasibility/value assessments at nominal cost

• Early-out checkpoints and options

• Money-back guarantees

Book your free demo

The best way to learn about The Lab’s patented Knowledge Work Standardization® approach is to book your free, no-obligation 30-minute screen-sharing demo. And you’ll get all your questions answered by our friendly experts. Simply call (201) 526-1200 or email info@thelabconsulting.com to book your demo today!